Introduction: The Rise of Collaborative Robotics

The industrial landscape is undergoing a major transformation, as companies seek smarter, more efficient solutions to meet the challenges of modern production. Traditional robots have served industries well by automating repetitive and high-precision tasks, but as industries evolve, the need for more adaptable solutions grows. Multi-robot collaboration is emerging as a crucial strategy to improve production efficiency, especially when combined with the flexibility of soft robotics. As demand for flexible, scalable, and highly efficient systems rises, the role of multi-robot collaboration becomes increasingly clear.

Multi-robot collaboration involves multiple robots working together in harmony to carry out tasks, sharing information and adjusting their actions in real time. These systems can increase productivity by automating complex workflows and optimizing operations. However, traditional robots can struggle with tasks requiring flexibility or delicate handling. This is where soft robotics offers a unique advantage. Unlike rigid robots, soft robots are flexible and adaptive, making them ideal for environments where collaboration, dexterity, and precision are key. The future of multi-robot collaboration lies in the integration of soft robots, which can work alongside traditional robots to perform a wide range of tasks efficiently.

Why Multi-Robot Collaboration is the Future

Industries across the globe are facing rising challenges such as increasing demand, labor shortages, and the need for cost-effective automation. Traditional robotic systems, while effective in some contexts, are often limited by their lack of flexibility. Multi-robot collaboration is the solution that enables industries to overcome these limitations. By combining the strengths of multiple robots, companies can optimize workflows, automate more tasks, and achieve greater productivity.

The core advantage of multi-robot systems is their ability to divide and conquer tasks. Different robots can specialize in different areas, such as sorting, assembly, material handling, or packaging. With soft robotics incorporated into these systems, robots gain the ability to adapt their movements and actions based on the material or task, improving both speed and quality. As a result, multi-robot systems become increasingly efficient and capable of handling more complex tasks.

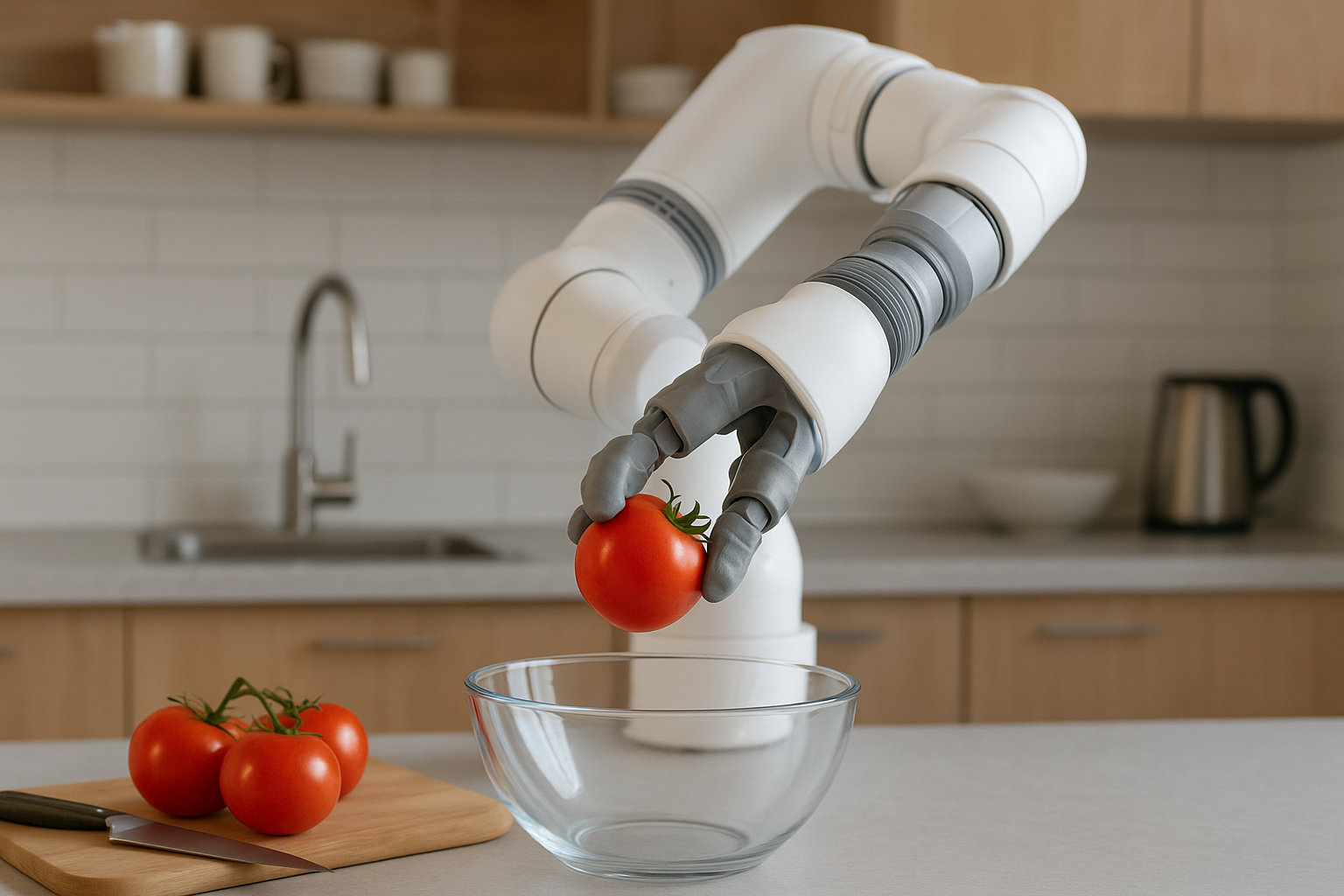

Soft robotics allows these robots to adjust their form and grip strength dynamically, making them capable of handling delicate materials that traditional robots would struggle with. Whether in the manufacturing of fragile electronics or the packaging of food products, soft robots are the perfect choice for industries seeking to automate delicate processes while maintaining high standards.

The Role of Soft Robotics in Multi-Robot Collaboration

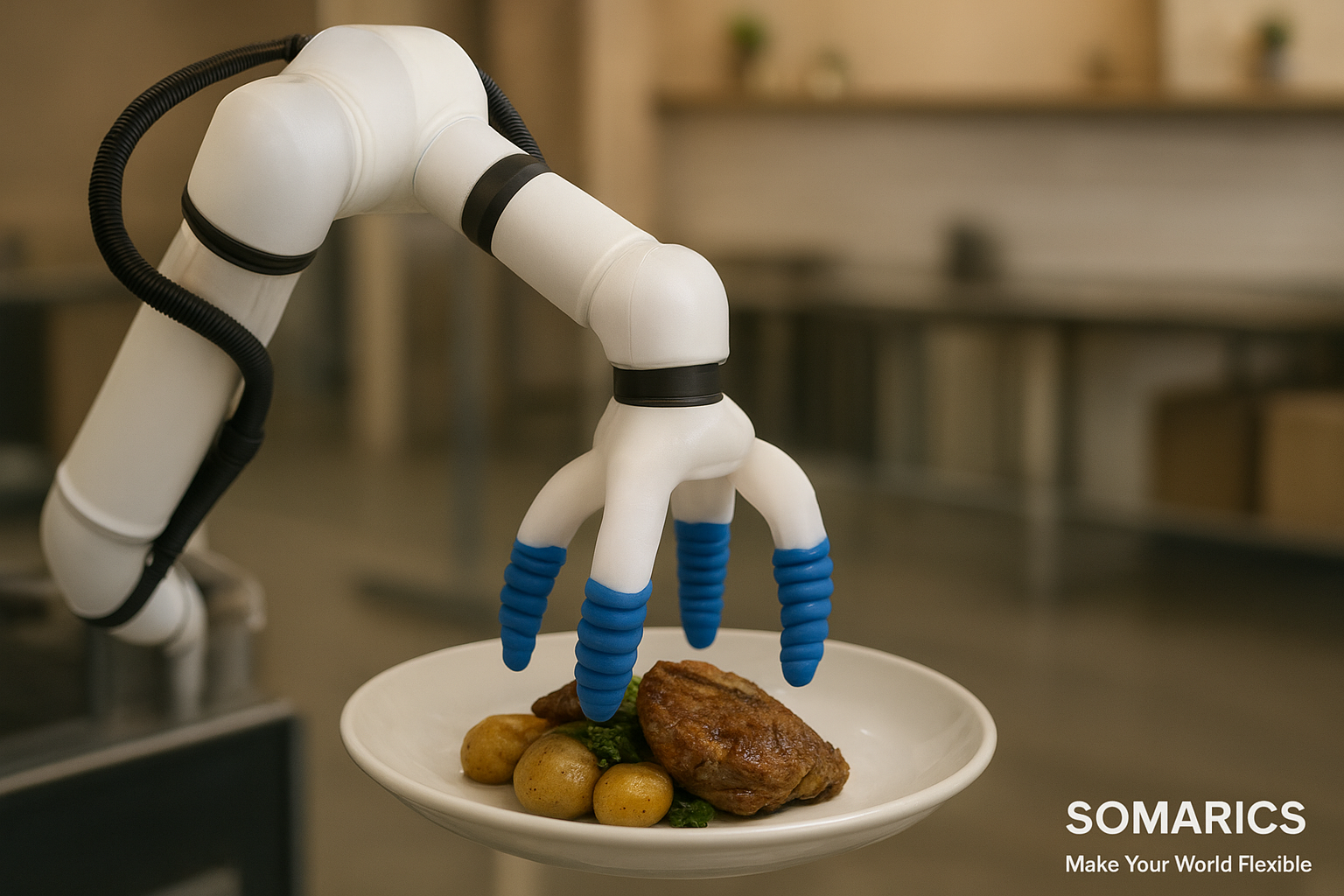

Soft robotics is a game-changer for industries embracing multi-robot collaboration. Soft robots use pneumatic actuators and flexible materials like silicone and rubber, giving them the ability to change shape, strength, and motion to suit a variety of tasks. Unlike traditional robots, which rely on rigid structures and movements, soft robots bring agility and dexterity to environments that require fine control.

In multi-robot collaboration, soft robots can work alongside traditional rigid robots to handle tasks that require greater flexibility. For instance, while a traditional robot might lift heavy objects, a soft robot can be assigned to tasks that require delicate handling, such as sorting fragile goods or packaging food. This cooperation allows industries to handle a wide variety of tasks more efficiently and safely, enhancing both workflow and overall productivity.

Soft robots’ ability to interact with humans is also a significant advantage. As collaborative robots (cobots) are increasingly integrated into workplaces, soft robots can assist human workers in a safe, adaptable manner. Their ability to work safely alongside humans makes them ideal for collaborative tasks in industries like electronics, automotive, and food processing.

How Soft Robotics Enhances Multi-Robot Collaboration in Various Industries

1- Increased Efficiency and Throughput

Soft robotics brings real-time adaptability to multi-robot systems. Unlike traditional robots that may need to pause or be reprogrammed for different tasks, soft robots continuously adapt to the needs of the environment. By operating autonomously and without the need for breaks, soft robots contribute to higher throughput, faster task completion, and minimized downtime.

Multi-robot systems powered by soft robots can handle high volumes of repetitive tasks in e-commerce fulfillment, manufacturing, and food packaging. The ability to scale operations and adjust to peak demand periods is a major advantage in industries that experience fluctuations in product volume and customer demand.

2- Handling Complex and Delicate Tasks

In industries that require handling delicate materials, soft robotics provides a crucial advantage. Electronics, pharmaceuticals, and food products all require specialized handling that traditional robots are often unable to provide. Soft robots can adjust their grip strength and form, ensuring that fragile items are handled without causing damage.

By working alongside traditional robots, soft robots enable multi-robot systems to take on both delicate and heavy-duty tasks, improving efficiency and reducing the risk of product damage.

3- Enhanced Flexibility and Adaptability

The flexibility of soft robots is one of their greatest strengths in multi-robot systems. In industries like custom manufacturing, small-batch production, and dynamic assembly lines, the ability to adapt to changing conditions is essential. Soft robots can be quickly reprogrammed to handle different tasks, providing industries with the agility needed to respond to changing demands and new challenges.

4- Improved Safety and Human-Robot Interaction

Soft robots provide an added layer of safety when working alongside human operators. Their gentle handling capabilities make them ideal for environments where workers interact closely with robots. This safety feature reduces the risk of injury, enabling soft robots to assist human workers with tasks that require precision and care, such as handling hazardous materials or assisting with packaging delicate products.

The Future of Soft Robotics in Multi-Robot Collaboration

As industries continue to expand and automate, the role of soft robotics in multi-robot collaboration will only grow. In the future, soft robots will become more intelligent, adaptive, and capable of real-time decision-making through the integration of AI and machine learning technologies. These advances will allow soft robots to collaborate more effectively with both traditional robots and human workers, driving further efficiencies across production lines.

We can expect soft robots to become a standard component in industries such as e-commerce, electronics manufacturing, food packaging, and automotive production. Their ability to adapt and collaborate with multiple robots will make them a cornerstone of future-proof automation systems.

Thus: Why Industries Need Soft Robotics NOW?!

The future of multi-robot collaboration relies on the flexibility, adaptability, and efficiency provided by soft robotics. By embracing this technology, industries can improve throughput, handle delicate materials, and ensure safer workplaces. The integration of soft robots into multi-robot systems will enable businesses to stay ahead of the competition and meet the growing demands of a fast-paced industrial environment.

To learn more about how soft robotics can transform multi-robot collaboration, visit SOMARICS Products and discover how our cutting-edge robotic solutions can help your business thrive.