The Complexity of Delicate Products

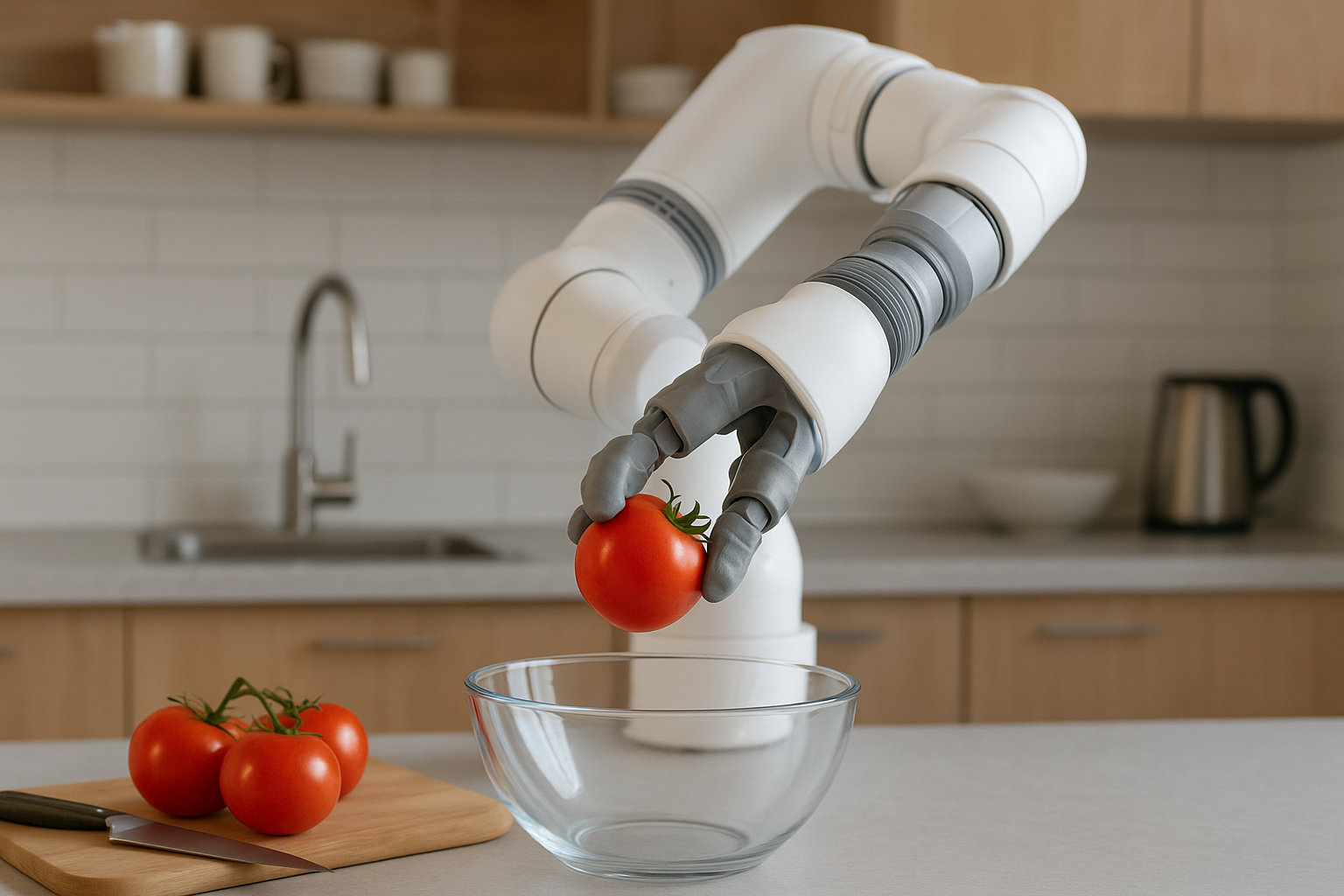

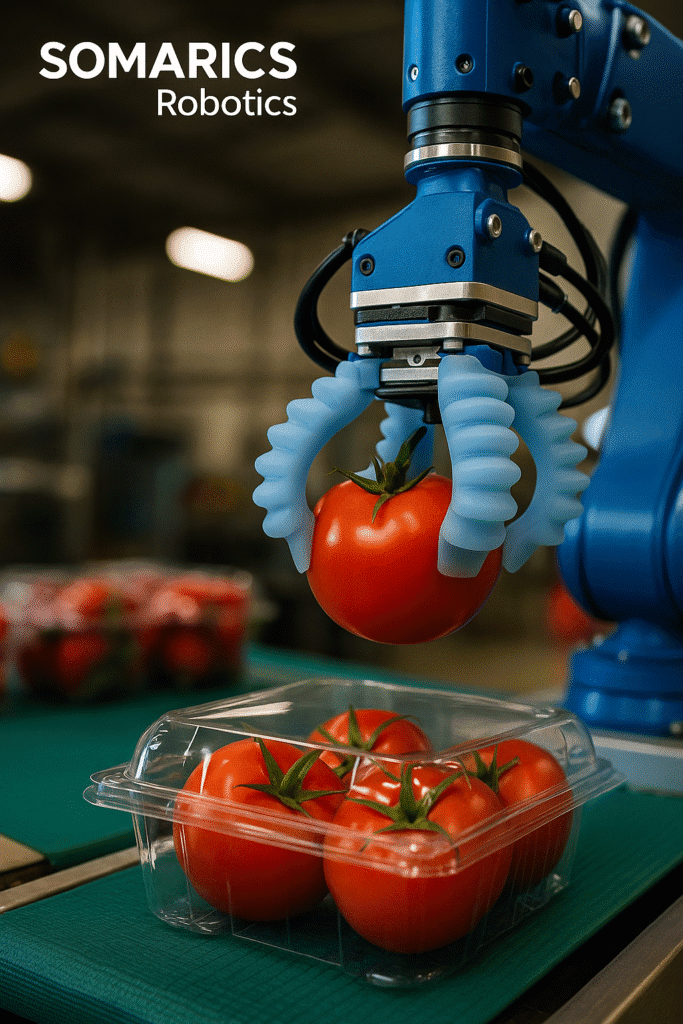

In structured industries like electronics or automotive, robots excel at repetition. But food — particularly fresh produce and baked goods — is a different beast. Strawberries roll unpredictably. Tomatoes bruise easily. Croissants deform with the slightest pressure. These inconsistencies make automation a challenge.

Traditional rigid grippers often fall short. They rely on fixed trajectories and cannot adapt on-the-fly. The result? Damaged goods, slower processing, and reliance on manual labor — all costly pain points.

Why Soft Robotics Is the Game-Changer

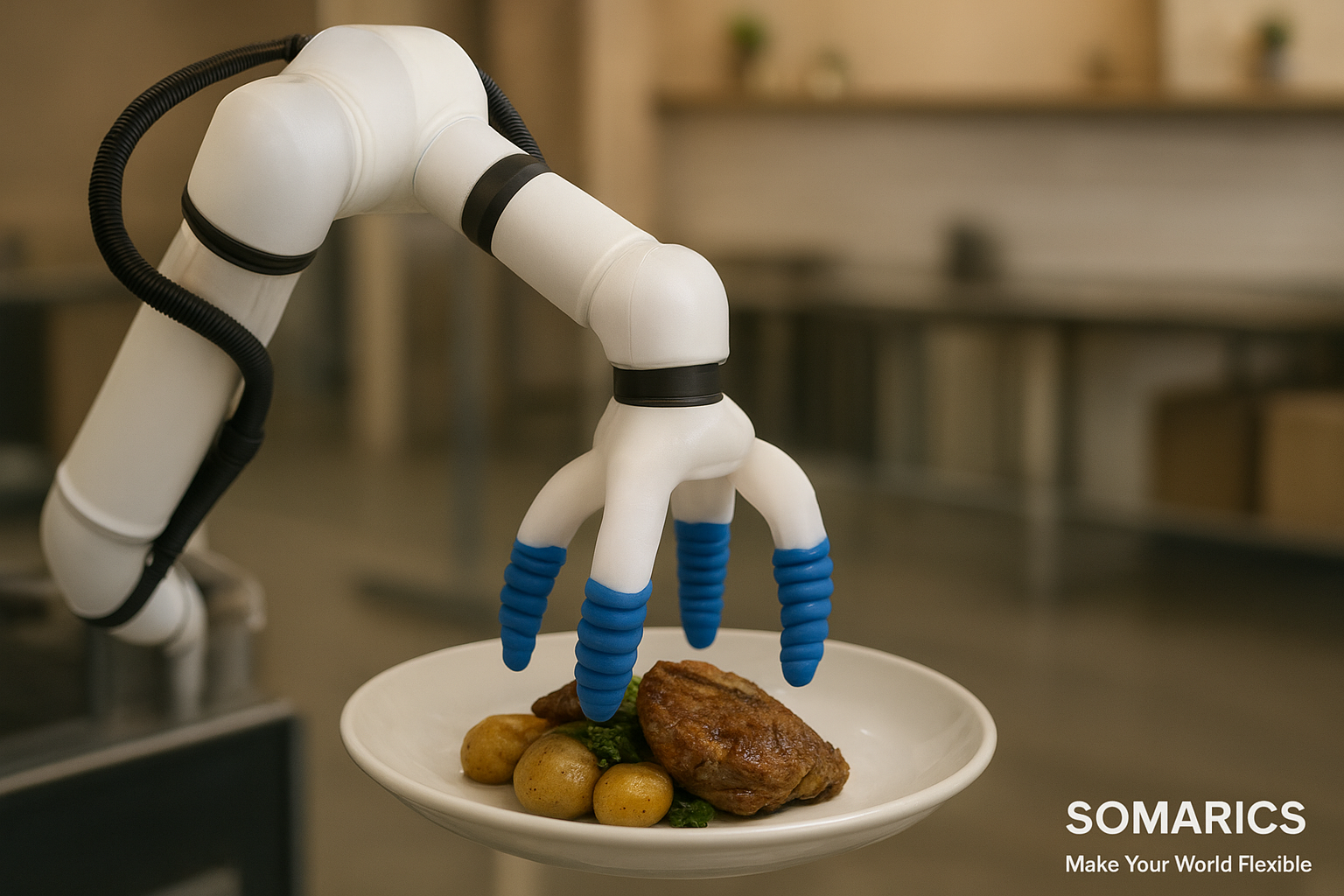

Soft robotic grippers, made of silicone or elastomeric materials, use pneumatic or tendon-driven actuation to conform to objects, not the other way around. This adaptability allows for gentle yet firm handling — a necessity for soft or irregular food products.

At SOMARICS, we tailor our designs based on product fragility, speed requirements, and integration constraints. A flexible gripper that handles ripe peaches today can be adjusted tomorrow to package trays of assorted pastries. That agility is the future of smart packaging.

Real-World Results: A Case from the Field

A packaging facility distributing berries in the Middle East faced labor shortages and rising waste. Manual sorting was inefficient, and fragile fruit was often bruised. We implemented a hybrid solution: vision-guided robotic arms equipped with SOMARICS soft grippers.

Within three weeks, the system was operational. It:

- Increased throughput by 42%

- Reduced bruising by 60%

- Enabled reassignment of 3 workers to higher-value QA roles

- Delivered full ROI in under 7 months

This wasn’t an isolated success. It represented a new standard for mid-sized operations under pressure to automate without sacrificing care.

Smart Packaging Demands Smarter Robots

Beyond picking and placing, modern food lines demand traceability, quality inspection, and line flexibility. Our systems combine:

- AI vision for ripeness and defect detection

- Adaptive packaging formats based on product dimensions

- Real-time monitoring via IoT integration

We’re actively piloting these technologies with partners across North America and the Gulf region, enabling manufacturers to future-proof their operations against both workforce volatility and shifting regulatory standards.

What Sets SOMARICS Apart

1. Labor Optimization

Fewer repetitive tasks, more human focus on logistics and quality.

2. Shrinkage Reduction

Clients report 15–30% less product damage, depending on product type.

3. Scalable Modularity

Reconfigure grippers seasonally or between product lines without replacing the whole system.

4. Hygiene and Compliance

All materials are FDA/EU compliant and cleanroom-compatible. Easily washable for high-throughput lines.

5. Energy and ESG Benefits

Pneumatic systems offer lower energy consumption, supporting sustainability mandates.

Speed vs. Effectiveness: A False Tradeoff

While rigid robots may boast faster cycle rates, soft robotic systems yield higher effective throughput — fewer damaged items, fewer stoppages, smoother operation. In small and medium-scale facilities, that means fewer disruptions and faster ROI.

Strategic Integration Pathway

At SOMARICS, our onboarding process includes:

- Workflow audit

- ROI estimation

- Custom soft gripper prototyping

- Seamless integration with your existing lines

Our systems are designed for fast deployment and measurable results. In past projects, clients realized ROI within 6–9 months and gained operational savings of up to 18% within the first year.

We also provide on-site and virtual training to upskill staff for tomorrow’s food tech roles.

Looking Ahead: The Future of Fresh Packaging

Expect rapid evolution in:

- AI-driven self-learning systems for adaptive handling

- Mobile packaging units deployable across facilities

- Advanced food-grade materials for greater durability

- Integrated traceability logs for compliance and analytics

- Pre-certified robotic modules for plug-and-play adoption

As regulations tighten and consumers demand more, soft robotics is no longer a “nice-to-have.” It’s your next productivity engine.

Final Thoughts

At SOMARICS Robotics, we’re committed to solving one of automation’s toughest challenges: the unstructured. Whether you handle fruits, bakery items, or mixed goods, our adaptive gripping solutions give you the edge.

Let’s turn your packaging line into a smart, scalable, and sustainable advantage.

To explore collaboration or pilot opportunities, contact our team today.