Introduction: The Critical Role of Last-Meter Automation in Urban Agriculture

As urban agriculture expands, from rooftop greenhouses to shipping-container farms, the challenge of last-meter logistics becomes increasingly visible. It’s not enough to grow food within the city; it must be harvested, sorted, packaged, and delivered quickly and affordably to local residents. The final stretch of this process, where labor shortages, contamination risks, and physical constraints collide, often becomes the costliest and most inefficient link in the supply chain.

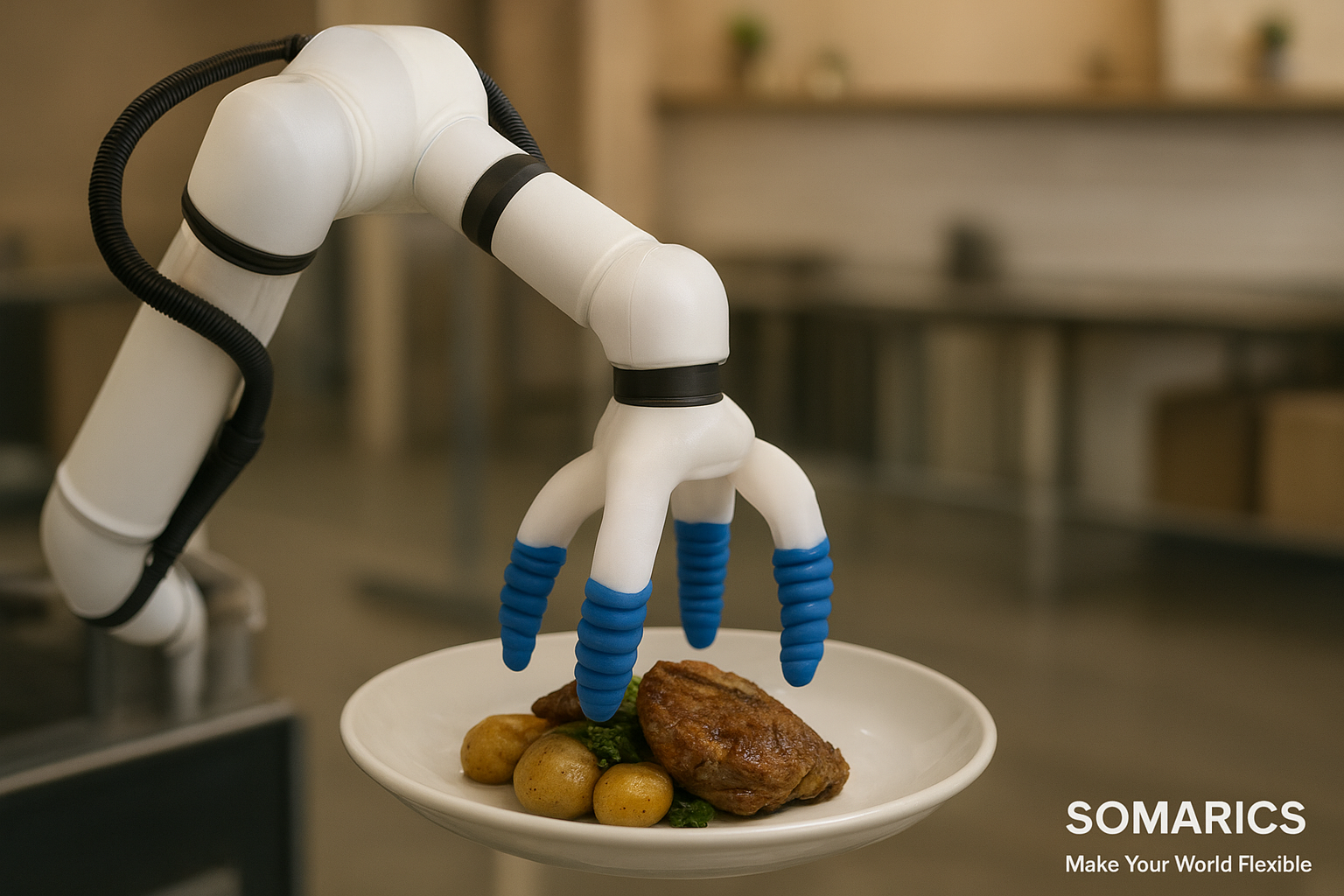

SOMARICS introduces a new frontier: soft robotic platforms designed to automate the delicate and high-variability tasks involved in the final moments of farm-to-fork. In this article, we explore how soft robotics, especially compliant grippers and adaptive packaging modules, can dramatically enhance the efficiency, hygiene, and economic viability of urban agri-logistics.

Why Urban Farming Demands a New Kind of Automation

Unlike traditional field agriculture, urban farms are compact, vertically structured, and space-constrained. Many use hydroponics or aeroponics inside closed-loop systems. Their key bottleneck is not planting or growth, it’s output handling.

Key Constraints:

- Tight working corridors between vertical grow racks

- Irregular harvest schedules depending on LED light cycles

- Variability in produce size and texture (e.g., microgreens vs cherry tomatoes)

- Need for immediate packaging to retain freshness and meet local demand

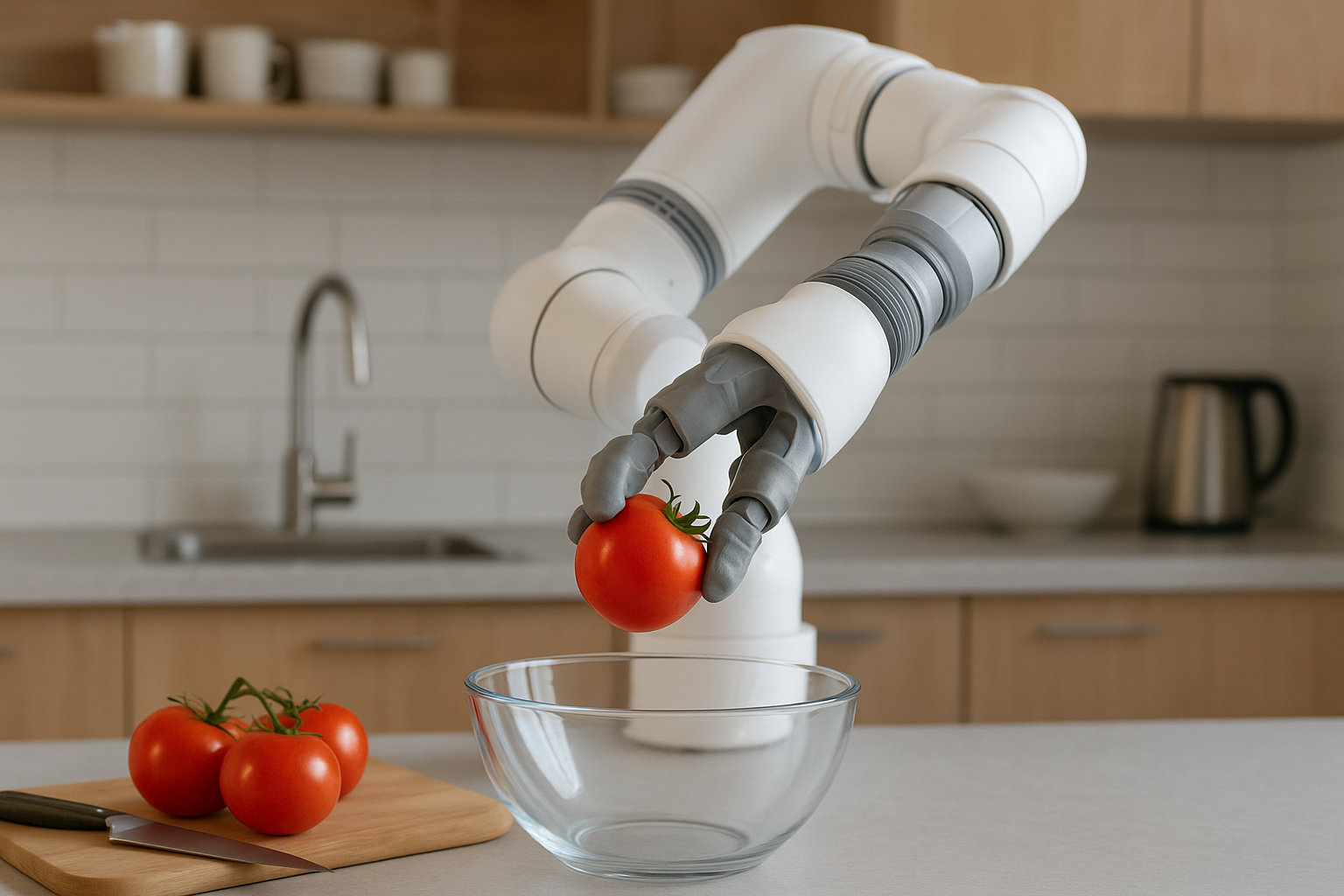

Traditional robotic arms are too bulky, rigid, and unsafe for these environments. Soft robotics, however, brings the ability to operate with millimeter-scale precision in confined, shared spaces without risking damage to produce or injury to human co-workers.

What Happens in the Last Meter? The Core Tasks

The ‘last meter’ refers to the stretch from the grow module to the packaging shelf, or from the harvest bed to the transport crate. Within this short distance, the following high-skill tasks take place:

1- Precision Harvesting

- Detecting ripeness with machine vision

- Applying appropriate grip force without bruising

2- Sorting by Grade and Weight

- Sorting leaves or fruits into different quality levels

- Diverting items for compost or donation if needed

3- Packaging for Micro-Distribution

- Grouping items by order

- Labeling, sealing, and preparing for electric bike or foot delivery

4- Sanitization and Hygiene Handling

- Operating in semi-sterile environments

- Avoiding direct human contact during peak illness seasons (e.g., flu, pandemics)

Beyond these immediate tasks, the last meter is where data becomes invaluable. Soft robotic platforms equipped with IoT sensors can log every interaction, harvest time, and grade, creating a digital twin of every tray harvested. This data not only informs compliance and traceability but also unlocks predictive maintenance and AI-based yield forecasting.

SOMARICS Soft Robotics Cells, Designed for Agri-Logistics

SOMARICS has engineered modular robotic cells that fit directly into grow spaces and logistics zones in urban farms. Each unit combines:

- Soft robotic grippers capable of dynamic force control

- Conveyor-tied packaging units

- AI-driven object recognition for ripeness and classification

- HEPA-enclosed micro-environments for sanitary operations

- Edge-computing modules for low-latency, cloud-optional automation

- API-level integration with farm management systems (FMS)

These units are:

- Battery-powered and solar-compatible for rooftop use,

- Stackable and reconfigurable to suit vertical farming racks,

- Cloud-optional for low-connectivity zones,

- Trainable in minutes by non-technical farm workers, and

- Serviceable on-site with modular plug-and-play components.

Their lightweight design allows for retrofitting into existing urban farming layouts without structural upgrades.

Economic and Operational Benefits

Urban agri-logistics is plagued by two main costs: labor and waste. Here’s how SOMARICS addresses both:

- Labor Efficiency: Reduces human handling by up to 70%

- Speed: One module processes 450 units/hour with minimal fatigue

- Yield Maximization: Avoids damage during handling, preserving up to 12% more sellable produce

- Data Logging: Tracks harvest and packaging data for traceability and compliance

- Hygiene Assurance: Minimizes contamination during flu season or in pandemic-sensitive zones

ROI Case Estimate: For a rooftop farm with 100 grow beds, SOMARICS automation pays for itself in 11 months. A slightly larger indoor hydroponic facility sees positive ROI in 7-9 months due to higher harvest frequency.

Additional Gains:

- Increases shelf-life by up to 18% due to reduced bruising,

- Facilitates hyperlocal branding (“harvested this morning” labels), and

- Reduces insurance premiums via operational risk minimization.

Target Applications and Customer Profiles

AgTech Startups

- Integrate SOMARICS modules into their controlled environment agriculture (CEA) systems.

- Offer robotics-as-a-service (RaaS) models for rapid urban expansion.

Fresh Food Delivery Platforms

- Automate packaging directly at the farm site for fresher delivery.

- Increase consistency and hygiene in boxed greens, mushrooms, and herbs.

City Governments and Smart Municipalities

- Equip municipal farms with last-meter automation to reduce public food program costs.

- Use ESG-compliant solutions to meet urban sustainability KPIs.

Non-Profit Urban Farms and Educational Institutions

- Use SOMARICS as a showcase of high-tech sustainability

- Promote STEM learning and tech-driven sustainability goals

Design Features for Urban Resilience

- Narrow-Form Robotic Arms: Maneuver between racks as narrow as 25cm

- Self-Cleaning Gripper Skins: Reduce microbial risk with antimicrobial elastomer coatings

- Dynamic Weight Sensing: Auto-calibration for delicate versus bulky items

- Integration APIs: Compatible with ERP and supply chain software

- Low-noise operation: Suitable for residential or rooftop environments

- Fail-safe modes: Ensures product safety even in partial system failure

- Sustainable Build: Built with recyclable polymers and bio-compatible gels

These features make SOMARICS solutions viable in rooftop farms, indoor shipping container farms, and even community garden logistics hubs.

ESG & Sustainability Considerations

SOMARICS robotic modules support cities aiming for sustainable and traceable food logistics:

- Environmental: Reduces food spoilage and plastic packaging needs

- Social: Creates high-tech maintenance jobs in underserved urban zones

- Governance: Enables transparent supply chains with automation logs

With cities like Toronto, Singapore, and Berlin pushing for food localization, SOMARICS soft robotics aligns directly with their public planning.

Conclusion: Closing the Urban Farming Loop with Soft Robotics

Smart urban farming isn’t just about growing; it’s about completing the loop from production to distribution. Last-meter agri-logistics, powered by soft robotics, offers a scalable, clean, and economically viable path forward.

By automating harvesting and packaging within the farm environment itself, SOMARICS is not only cutting costs and waste, but it’s helping cities reinvent food resilience.

With predictive analytics, traceable harvest logs, and plug-and-play integration into urban infrastructures, SOMARICS isn’t just building tools; it’s building the backbone for resilient food supply in the densest parts of our planet.

The future of urban food security will not be built by crops alone, but by how we harvest, handle, and hand over what we grow. With SOMARICS, the last meter is no longer the weakest link. It becomes the smartest one.

Please feel free to contact us. We have simplified our contact form for you: Contact us!