(A SOMARICS Perspective)

Introduction: Why Complex Manual Tasks Are the Next Automation Frontier

Across global industries, from advanced manufacturing in Ontario to high-density logistics hubs in Singapore, one segment of work remains stubbornly difficult to automate: complex manual tasks. These are the operations that combine variability, delicacy, and human-like decision-making. They are the “last bastion” of human labor in automation-heavy sectors, and for decades, they have resisted mechanization.

Yet the global labor landscape is shifting. Chronic workforce shortages, combined with rising quality standards and ESG-driven operational transparency, are forcing industries to rethink how these tasks are handled. Simply throwing more human labor at the problem is no longer sustainable. And conventional rigid robotics, designed for repeatable, pre-programmed tasks, cannot adapt to the unpredictability inherent in this category of work.

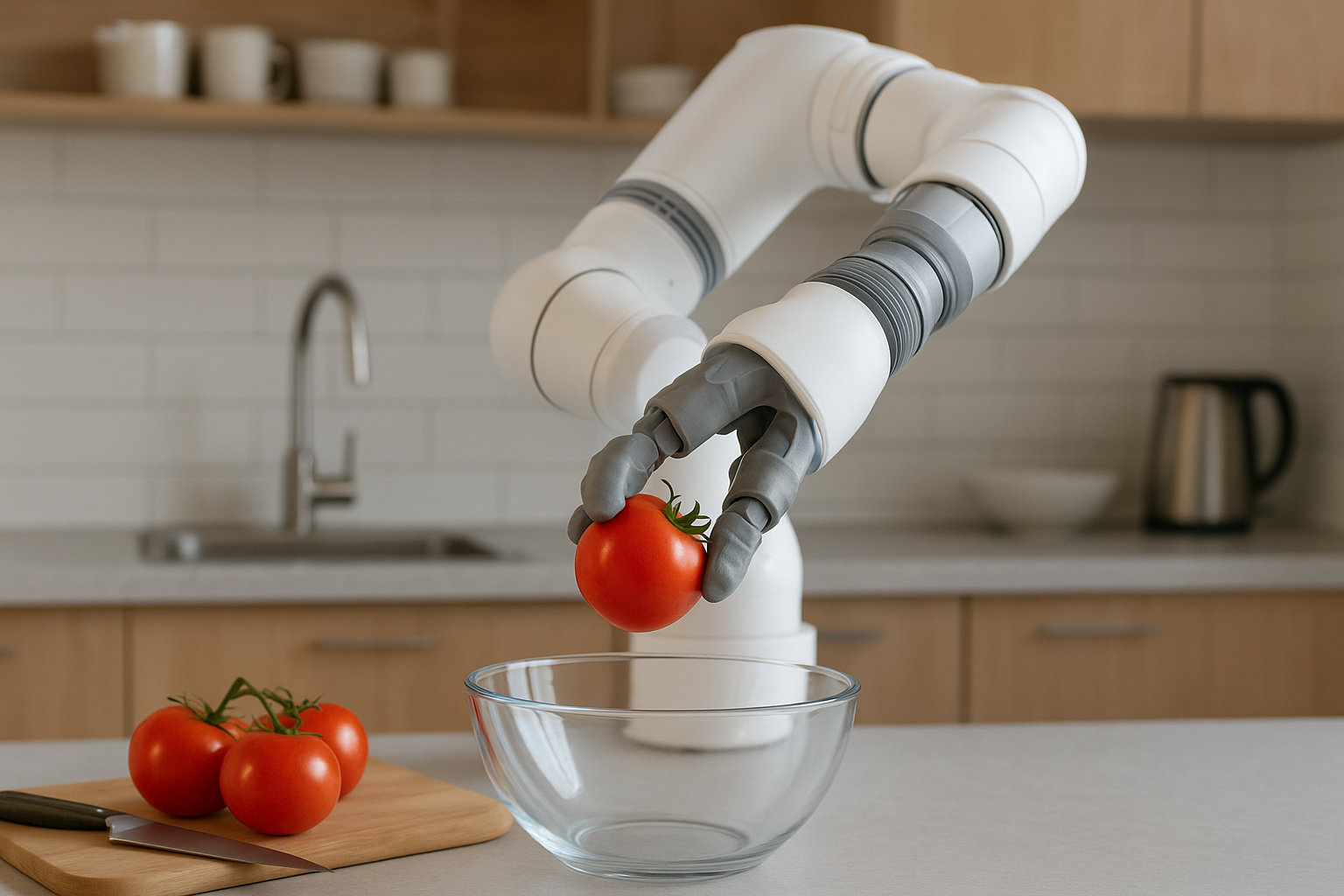

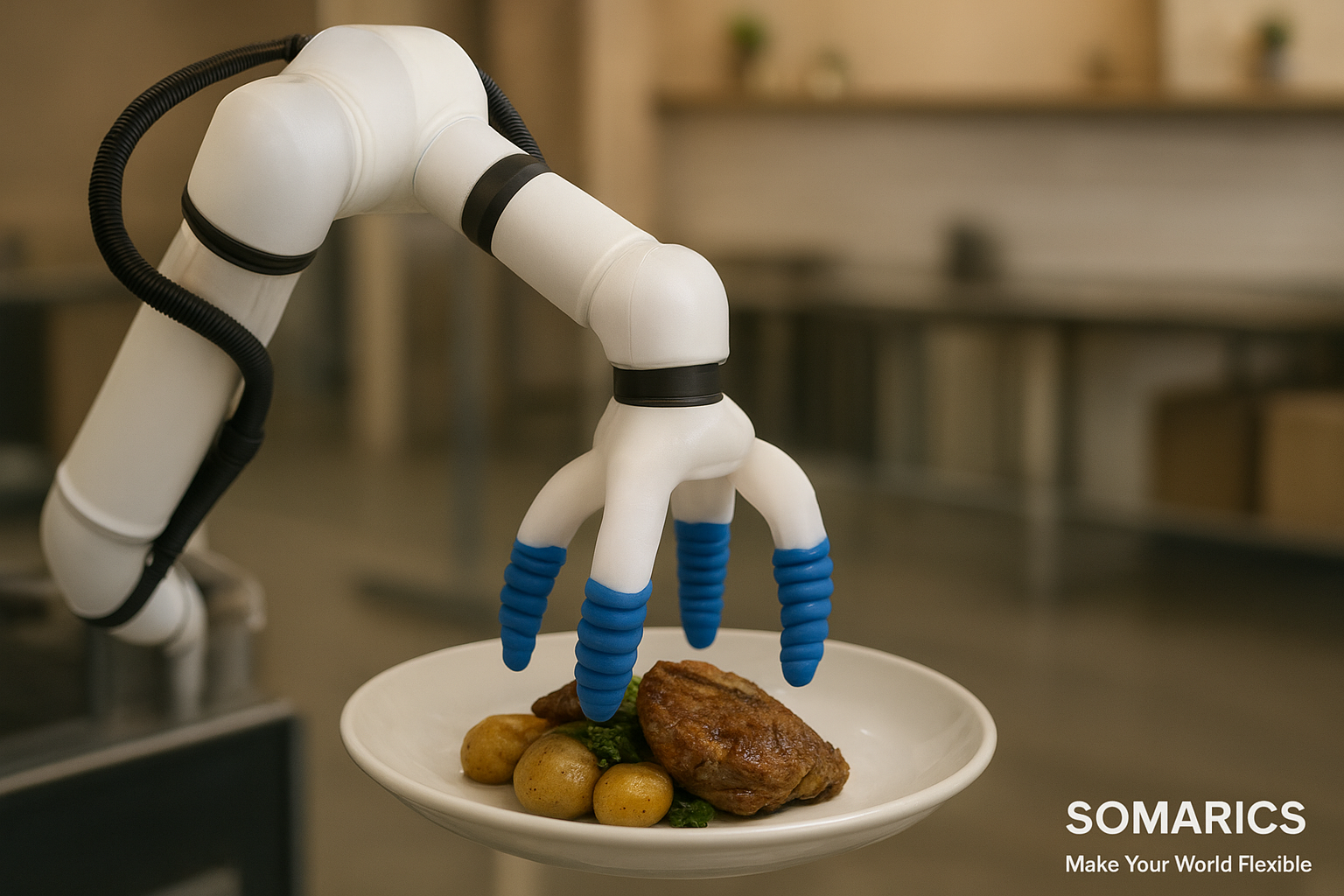

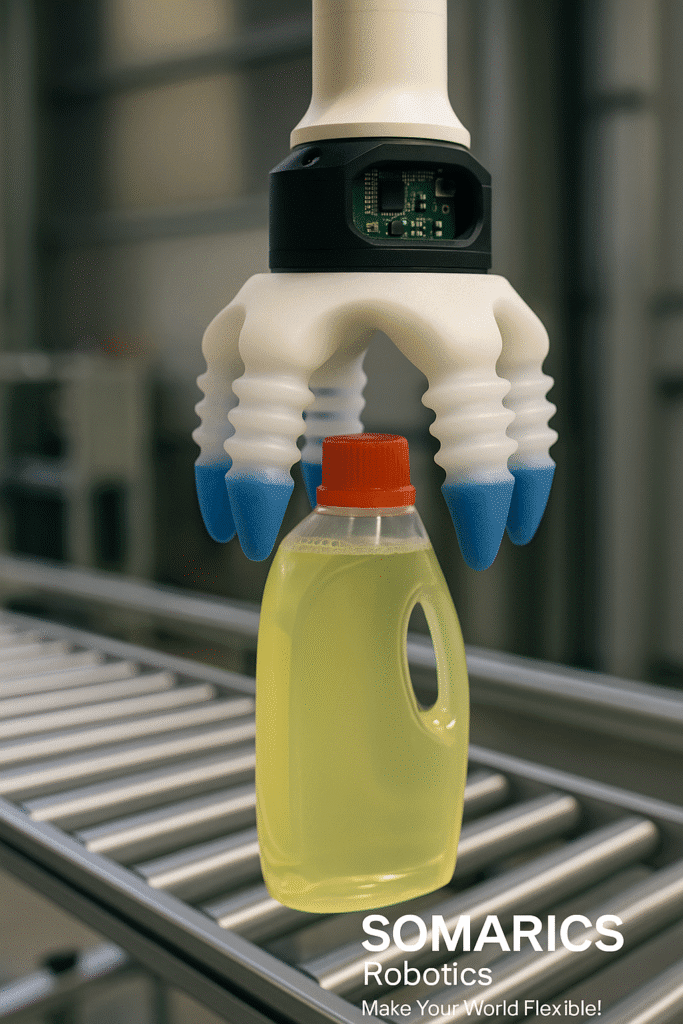

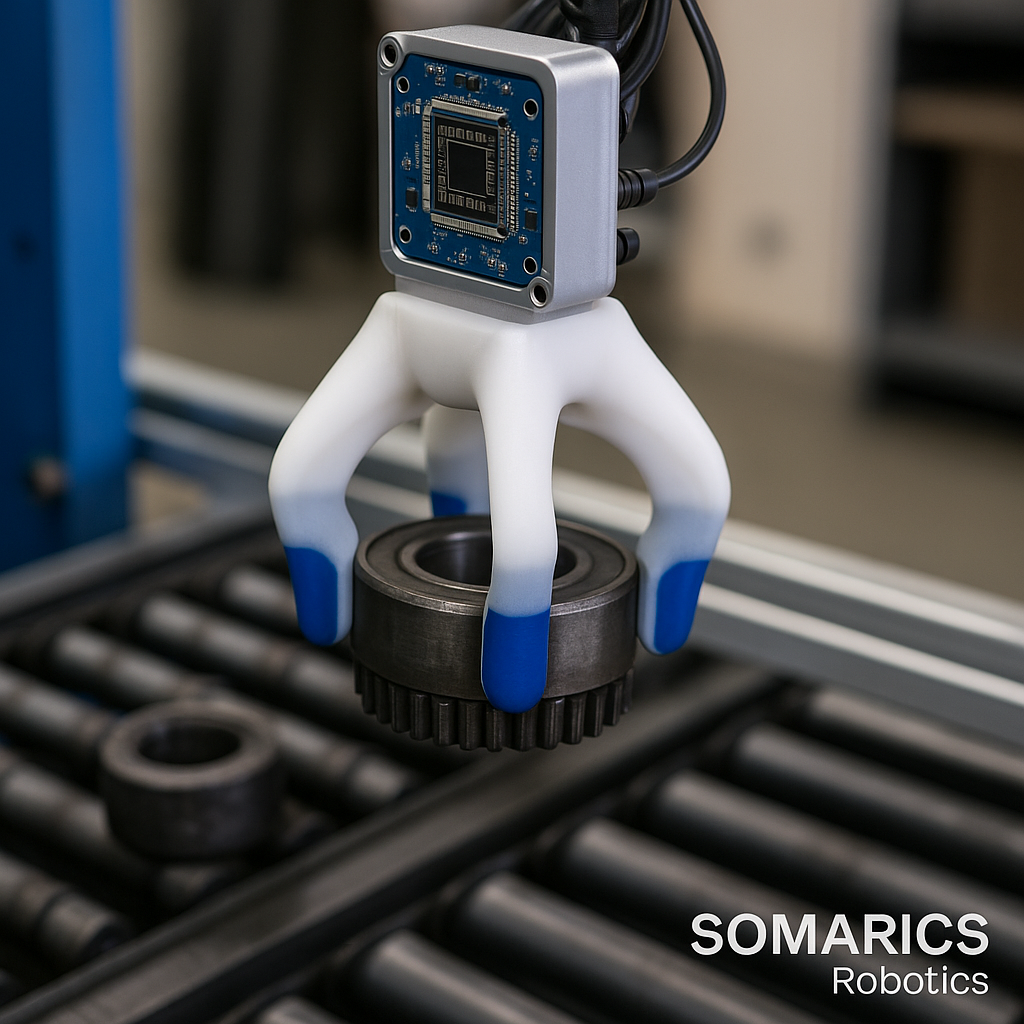

At SOMARICS, we believe the solution lies in autonomous soft end-effectors, robotic grippers and manipulation modules that combine compliant materials, embedded sensing, and AI-driven control. These systems are designed not merely to automate, but to adapt in real time to changing conditions, product variations, and complex handling requirements.

Defining Complex Manual Tasks in Industrial Contexts

In an industrial setting, complex manual tasks are characterized by at least three of the following:

- Object Variability – Items differ in size, shape, texture, or fragility within the same production run.

- Environmental Constraints – Operations occur in tight spaces, shared human-robot environments, or irregular layouts.

- Dynamic Decision-Making – Operators adjust handling techniques based on real-time sensory input.

- Safety-Critical Handling – Errors can cause damage, contamination, or injury.

Examples:

- Picking and packaging assorted fresh produce from mixed bins.

- Assembling fragile electronic components with sensitive connectors.

- Handling soft, irregular raw materials in food processing.

- Sorting high-value items for e-commerce orders with no two packages alike.

Historically, such tasks have relied heavily on human dexterity and tactile judgment. The missing element in automation has been the ability to adapt mid-task without human intervention, something soft robotics now makes possible.

Why Soft End-Effectors Matter

Traditional rigid end-effectors excel in high-speed, uniform tasks but falter when object variability or fragility enters the equation. Soft end-effectors, on the other hand, are built from compliant, deformable materials that can conform to the object’s geometry while applying controlled force.

Key Functional Advantages:

- Compliance-Driven Grip – Reduces the risk of crushing or slipping.

- Multi-Surface Contact – Evenly distributes force across irregular shapes.

- Embedded Sensing – Integrates tactile, force, and sometimes temperature sensors.

- Self-Adjusting Actuation – Pneumatic or tendon-driven mechanisms that dynamically respond to resistance or slippage.

From a future foresight perspective, the next 5–15 years will see rapid convergence between material science (creating softer, more durable gripper skins), embedded AI (real-time decision-making), and distributed automation architectures (edge-based control for low latency). This will enable autonomous soft end-effectors to replace or augment human hands in far more scenarios than today.

From Semi-Automation to Full Autonomy

The journey toward fully autonomous soft end-effectors is evolutionary:

- Operator-Guided Automation – The end-effector handles the mechanical task, but a human guides selection and positioning.

- Sensor-Augmented Autonomy – Vision and tactile data allow the gripper to adapt grip force and positioning without constant human input.

- Task-Level Autonomy – The end-effector identifies, picks, manipulates, and places items independently within defined work zones.

- Adaptive Multi-Task Autonomy – The system dynamically reassigns itself to different tasks in the same workflow based on priority and environmental conditions.

SOMARICS’ roadmap emphasizes that moving from stage 2 to stage 4 is not just a matter of better AI, it requires tight integration between hardware compliance, sensing fidelity, and control algorithms.

The SOMARICS Approach to Autonomous Soft End-Effectors

At SOMARICS, we design our autonomous soft end-effectors with three guiding principles:

- Adaptive Interaction – Every grip is calculated based on the object’s live feedback profile, not just a pre-set force curve.

- Seamless Integration – End-effectors are modular, plug-and-play with existing robotic arms or SOMARICS’ own soft manipulators.

- Operator-Friendly Configuration – Setup and task training are no-code, enabling rapid re-tasking by non-specialist staff.

Core Technical Modules:

| Module | Function |

| Compliant Grip Surface | Made from food-grade, wear-resistant elastomers with antimicrobial properties. |

| Pneumatic Micro-Valve Array | Enables zone-specific pressure modulation for partial-surface grips. |

| Multi-Modal Sensors | Combines force, slip, and proximity detection for safer handling. |

| Edge AI Processor | Runs trained models locally for millisecond decision-making. |

| Self-Calibrating Mount | Ensures quick alignment across different arm models. |

Applications Across Industries

Autonomous soft end-effectors are inherently cross-sector technologies. The same compliance and sensing features that handle a ripe strawberry can handle a fragile PCB or a set of small mechanical fasteners.

1. Food and Beverage

- Picking assorted bakery items without deformation.

- Sorting mixed produce into retail-ready packs.

- Loading irregular frozen goods into cartons.

2. Electronics Manufacturing

- Placing capacitors, chips, and connectors with controlled grip.

- Handling partially assembled units without stressing solder joints.

3. E-Commerce and Logistics

- Sorting unordered mixed SKUs into delivery bins.

- Managing returns with unpredictable packaging conditions.

4. Agriculture

- Selective harvesting of fruits at varying ripeness levels.

- Handling delicate seedlings during transplanting.

Market and ESG Alignment

From a marketing and investment standpoint, autonomous soft end-effectors directly support:

- Environmental Goals (E) – Reducing product waste from handling damage.

- Social Goals (S) – Enhancing worker safety and enabling upskilling.

- Governance Goals (G) – Providing traceable, logged handling data for compliance.

Impact investors and ESG-focused municipal programs increasingly prioritize automation that aligns with sustainability and inclusivity. This makes SOMARICS’ solutions attractive not just technically, but strategically.

Quantified Benefits – Validated in Early-Stage Tests and Simulated Pilots

| Metric | Observed Value | Validation Context |

| Reduction in Product Handling Damage | 14–19% | Observed in lab-scale trials with mixed produce and fragile packaged goods |

| Task Switching Time | < 3 minutes | Measured in internal pilot setups with no-code configuration |

| Operator Training Success (First Week) | 96% | Based on internal tests with non-technical staff |

| Energy Efficiency Improvement | 11–15% | Recorded in pneumatic control optimization simulations |

| Noise Output During Operation | < 42 dB | Measured in lab testbed for indoor food handling |

Note: All figures are based on SOMARICS’ internal simulations, lab-scale validations, or controlled pilot environments. Values may vary by application and integration.

Competitive Edge: What Makes SOMARICS Different

From the standpoint of sales strategy, our differentiation lies in:

- Adaptability First – Designed for high-mix, low-volume workflows where rigid robotics fail.

- Integration Without Disruption – Fits into existing infrastructure with minimal downtime.

- Validated ESG Benefits – Measurable reduction in waste and improvement in workplace safety.

Future Outlook (5–15 Years)

From a foresight perspective, the trajectory of autonomous soft end-effectors includes:

- Material Intelligence – Grippers that self-heal micro-tears or adjust surface texture in real time.

- Collaborative Autonomy – Networks of end-effectors coordinating across multiple work cells without central control.

- AI + Vision Fusion – Combining hyperspectral imaging with tactile feedback for next-level object understanding.

- Self-Upgrading Control Firmware – Remote learning updates based on aggregated fleet performance.

Industries that adopt early will not only solve labor challenges, but they will redefine their competitive position.

Conclusion: From Hands to Hybrid Intelligence

Complex manual tasks have long been the “final frontier” of automation. With autonomous soft end-effectors, that frontier is now moving. These systems combine the adaptability of human touch with the reliability of industrial automation, creating a hybrid intelligence that’s ready for the challenges of modern production.

At SOMARICS, we are committed to developing solutions that go beyond replacing labor, they elevate operations, improve product quality, and align with the ESG priorities shaping the next industrial decade.

🔗 Ready to explore how autonomous soft end-effectors can transform your complex workflows?

Contact SOMARICS to discuss pilot programs and integration pathways.