Introduction

Global food security is entering an unprecedented phase of vulnerability and complexity. By 2035, it is projected that more than two billion individuals will inhabit regions increasingly affected by extreme climate phenomena, armed conflicts, disrupted supply chains, and severely damaged infrastructure. In such volatile conditions, the challenge is no longer just growing enough food, but ensuring that this food can be processed, handled, and delivered with minimal dependency on stable labor, reliable electricity, or intact transportation networks. Traditional industrial models collapse under these pressures.

In this high-risk context, building food systems that are modular, flexible, and resilient is not a luxury, but a matter of survival. Soft robotics, long viewed as a laboratory curiosity, is proving to be a key enabling technology. This article explores how SOMARICS, an innovator in soft robotic automation, is developing solutions specifically optimized for emergency deployment in disrupted environments where every hour, every calorie, and every human life counts.

Why Crisis Zones Require a Different Kind of Automation

Automation, as we know it, was never designed for crisis zones. Most industrial automation systems assume stable infrastructure, predictable workflows, constant power supply, and skilled human operators. These assumptions collapse in emergency contexts.

Crisis zones are defined by characteristics that render traditional systems ineffective:

- Power infrastructure is intermittent, unreliable, or non-existent.

- Skilled human labor is either unavailable or at serious risk.

- Sanitation requirements are high due to the risk of disease outbreak.

- Equipment must be relocated rapidly, often through unstable terrain.

- System failures must be tolerable and recoverable with minimal intervention.

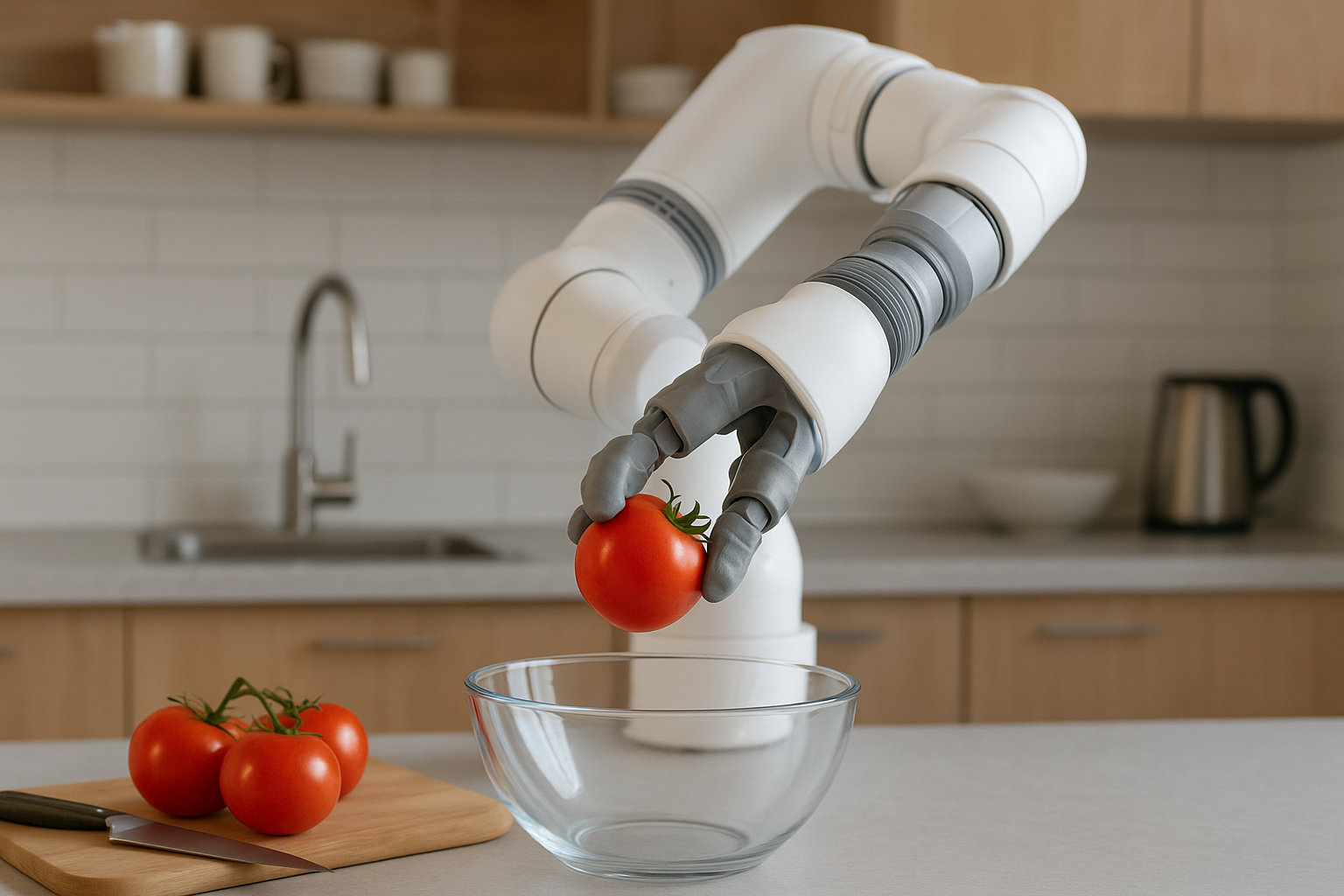

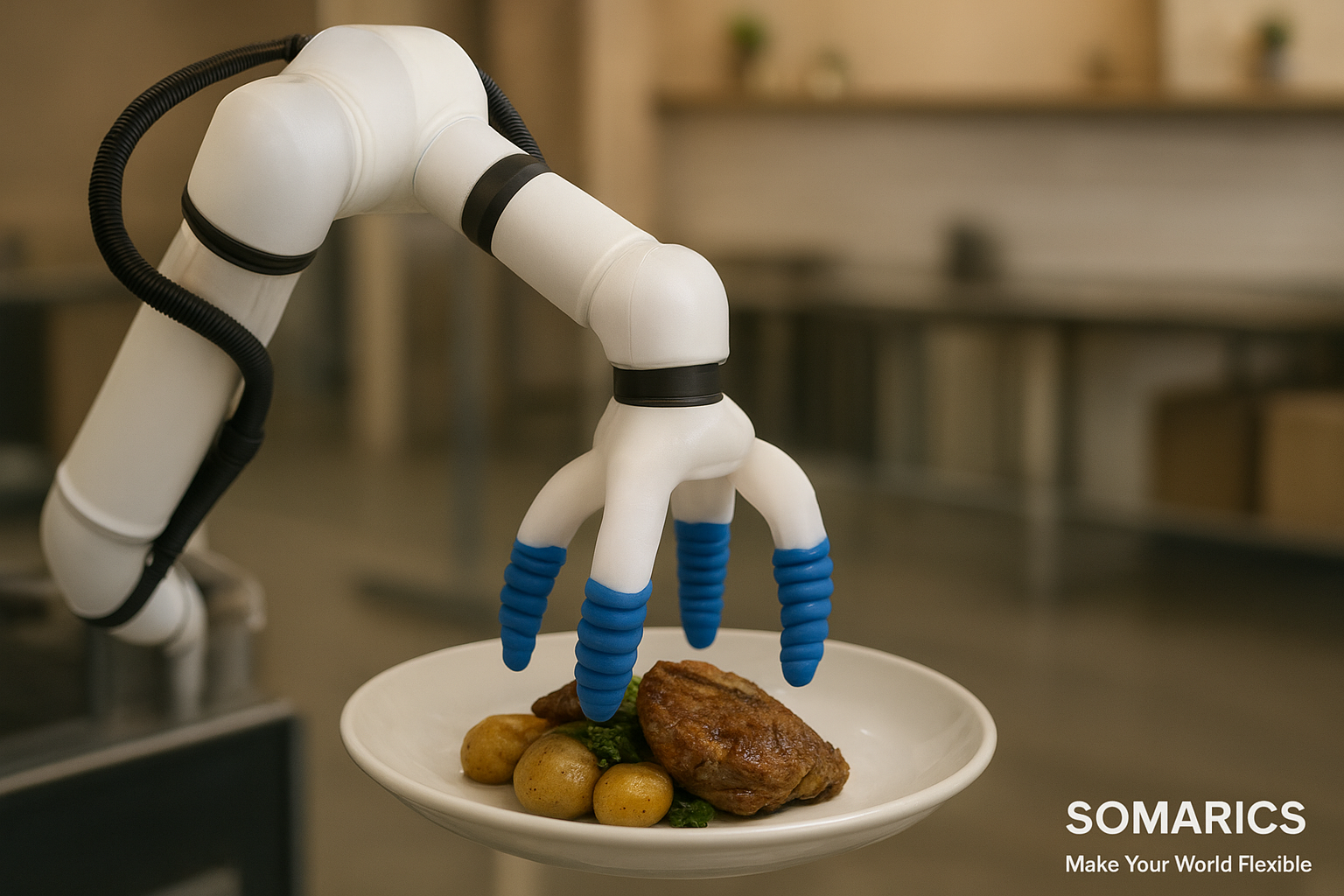

Soft robotics introduces a paradigm shift. Unlike rigid machines, soft robots are inherently safe around humans, flexible in the face of environmental variability, and capable of performing delicate handling tasks in chaotic settings. Their mechanical compliance allows them to operate safely in close proximity to human workers, fragile goods, and variable supply inputs. The technology behind SOMARICS builds on these attributes, designing automation that thrives where others fail.

The Core Challenge: Ensuring Emergency Food Supply in the Harshest Environments

In areas hit by floods, earthquakes, armed conflict, or political collapse, centralized food distribution networks often break down. Transport trucks can’t access damaged roads. Airports are congested or destroyed. Warehouses are empty or inaccessible.

Under these conditions, humanitarian response teams must:

- Establish micro-factories within 48 to 72 hours, often in tents or container units.

- Avoid relying on large human teams, both for safety and logistical efficiency.

- Prevent contamination, especially when food must be served to malnourished, immunocompromised, or injured individuals.

- Scale quickly, sometimes from serving 100 people to 10,000 in under a week.

Legacy systems break under such constraints. And while aid convoys from international agencies may take days or weeks, decentralized and localized automation offers a practical and fast solution.

SOMARICS’ Solution: Portable, Modular Soft Robotic Cells

SOMARICS has engineered a class of automation systems specifically tailored for field deployment. These are not bulky industrial arms or stationary installations; they are foldable, modular, and transport-ready robotic pods that combine smart software with soft actuators.

Key characteristics include:

- Compact design: Each robotic unit folds into a standard-size ruggedized container.

- Energy autonomy: The system runs on hybrid solar-battery packs, requiring no grid connection.

- Task flexibility: Each module can perform food handling, sorting, small-item packaging, or transfer tasks with a simple change of end-effector or software preset.

- Safe for untrained workers: With intuitive UI and built-in compliance, local volunteers can interact with systems safely without weeks of training.

These pods are designed for extreme simplicity, enabling non-engineers to set them up and reprogram them with visual interfaces, even when internet access is unavailable.

Specific Applications of Soft Robotics in Crisis Operations

1. Sterile Packaging of Emergency Food

In relief contexts, food items like protein bars, boiled eggs, fruits, or hydration gels must be packaged without human contact. SOMARICS grippers:

- Use medical-grade silicone tips for contact safety.

- Operate inside sealed environments fitted with HEPA filters.

- Offer precision and consistency that dramatically reduces contamination.

2. Medical Nutrition Handling

For malnourished children or trauma patients, food is medicine. Incorrect portions can cause harm. SOMARICS systems:

- Dispense exact quantities of powdered milk, vitamin mixtures, or therapeutic paste.

- Eliminate cross-contamination through modular tip changes.

- Log all actions digitally, creating traceable audit logs for compliance.

3. Sorting and Inventory of Relief Goods

Relief containers often arrive with mixed contents, including gloves, syringes, food, medicine, and clothing all jumbled together. Soft robotic arms:

- Use embedded vision systems to classify and sort items by type, size, and urgency.

- Sort faster and more accurately than stressed human teams.

- Reduce the risk of damage to fragile or perishable items.

4. Cross-Sector Use Cases

While humanitarian missions are the immediate use case, the same technology supports:

- Defence logistics in forward operating bases.

- Disaster preparedness hubs are run by national governments.

- Mobile clinics operated by health NGOs.

Off-grid food services for arctic missions, desert expeditions, and extreme tourism.

Real-World Simulation: Flood Relief Deployment in South Asia

In collaboration with a UN-partnered disaster response NGO, SOMARICS deployed a prototype robotic pod in a mock emergency village modeled after a post-flood scenario in Bangladesh.

Results:

- Time from container landing to full operational status: 6 hours

- Within 24 hours:

- 4,500 meals packaged

- 1,200 hygiene kits sorted

- 750 vitamin packets distributed

More importantly:

- Local labor demand was reduced by over 60%

- Contamination incidents dropped to near-zero

Solar power was sufficient for continuous operation

Economic Viability and Investor Perspective

The humanitarian technology market is growing exponentially. With rising climate shocks, pandemics, and armed conflicts, governments and NGOs are allocating record funds to mobile, resilient infrastructure.

By 2035:

- Market for rapid-deploy food and medical automation will exceed $210 billion

- Funding from: World Bank, USAID, EU Disaster Relief, Red Crescent, Climate Adaptation Funds

- Private sector players: Defence contractors, pharmaceutical logistics, clean tech accelerators

SOMARICS offers dual-use ROI:

- Public sector: rapid-deploy resilience systems

- Private sector: portable automation for agri-food, pharma, and logistics

For forward-thinking investors, this is not just an opportunity; it is a hedge against a future defined by volatility.

Design Considerations for Harsh Field Conditions

1. Durable Materials

- All grippers use food-grade, anti-microbial silicone.

- Frame built with corrosion-resistant alloys and impact-tolerant polymer.

2. Operational Redundancy

- All critical actuators and sensors have backups.

- The modular power and control architecture allows for hot-swapping.

3. Field Repairable

- Replacement parts designed for a 5-minute swap without tools.

- Maintenance protocols require less than 3 hours of training.

4. Data-Lite Smart Interfaces

- Built-in onboard inference engine for vision and control.

- No need for real-time cloud connectivity; perfect for offline regions.

ESG and Strategic Impact

Environmental Benefits:

- Solar compatibility lowers the carbon footprint.

- Precise portioning reduces food waste.

Social Impact:

- Lowers health risk to volunteers and workers.

- Enables skill transfer to local technicians.

Governance Advantage:

- Automation logs ensure transparency and traceability.

- Facilitates compliance with humanitarian and environmental standards.

These factors make SOMARICS an ideal partner for ESG-aligned venture funds and impact-driven governments.

Why This Matters Now?!

In a world increasingly defined by disruption, pandemics, wars, megastorms, and migration, resilience technology is no longer a side bet. It is the core thesis.

SOMARICS’ soft robotic systems offer what today’s fragile food ecosystems desperately need: automation that can be deployed anywhere, by anyone, under any condition.

Unlike vaporware or R&D-stage platforms, SOMARICS is building real systems for real crises—modular, human-safe, and market-ready.

Conclusion: Automation for the Fragile Future!

As the climate crisis escalates and geopolitical fragmentation deepens, food security will depend not just on what we grow, but on how we handle it, and where we can do so reliably.

Soft robotics is the enabling layer for this new paradigm. Not through brute force, but through adaptability, compliance, and smart modularity.

SOMARICS is not just building robotic tools. We are building infrastructure for resilience, and with it, the capacity to feed and protect the most vulnerable populations on Earth, today, not tomorrow. For every leader, investor, or innovator concerned about food security and climate adaptation, soft robotics is not an optional future.

It is the intelligent path forward.