Introduction: A practical challenge, a technological response

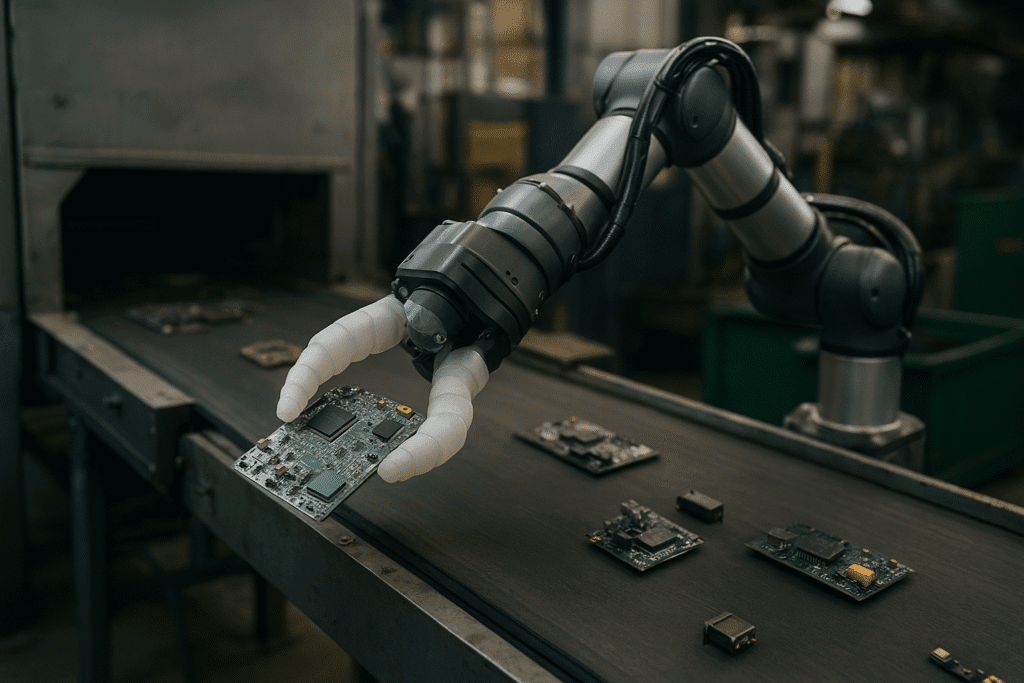

Electronic waste and hazardous industrial waste present a persistent and growing operational challenge for recycling systems worldwide. Discarded electronics contain recoverable metals and components as well as toxic substances; lead, mercury, cadmium, brominated flame retardants, and residues from batteries and capacitors. These mixed streams are difficult to process with high yield using conventional methods. Manual sorting exposes workers to dust, sharp fragments and chemical residues; conventional rigid automation tends to damage recoverable parts or requires extensive pre-sorting and fixturing.

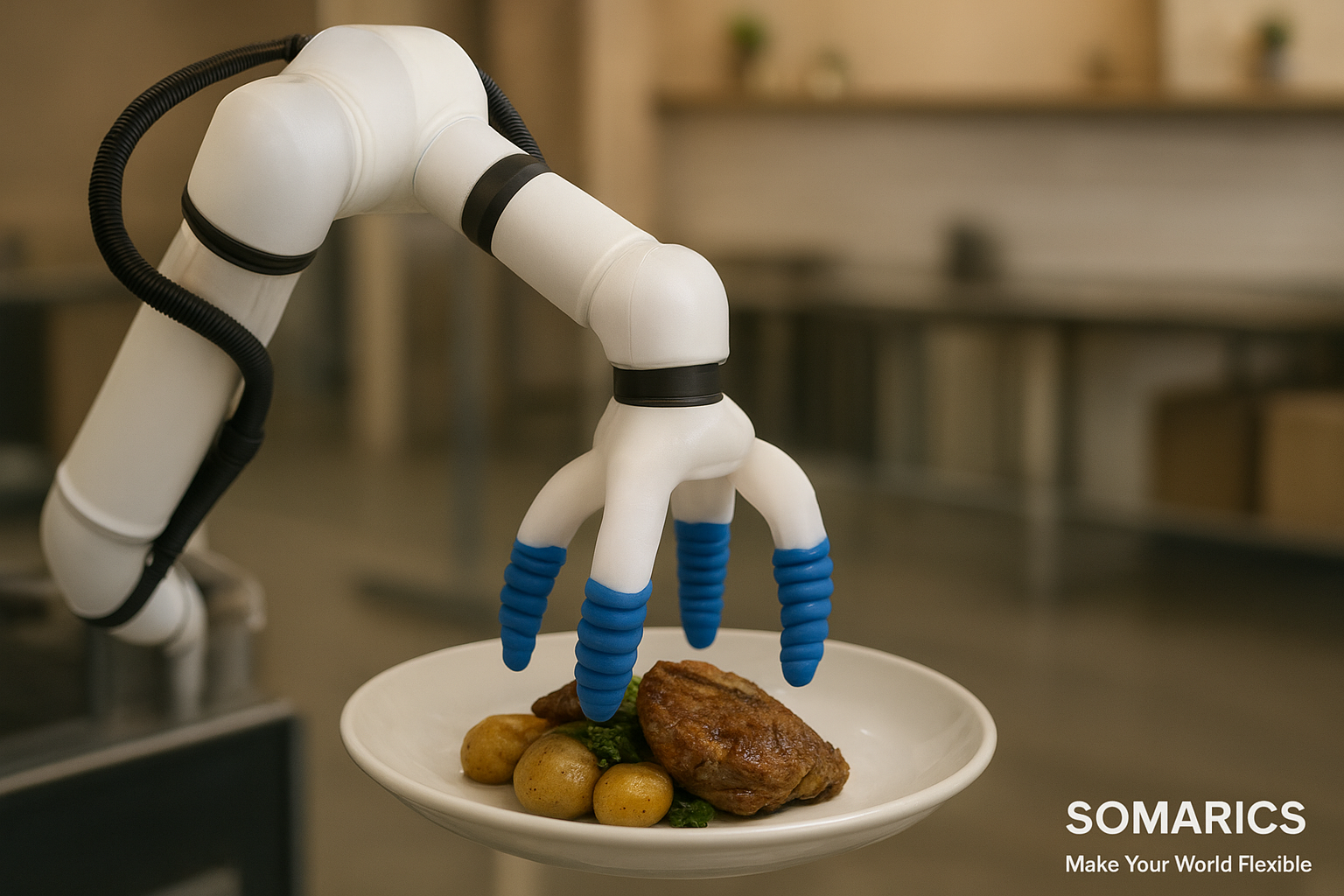

Soft robotic systems, compliant manipulators driven most commonly by pneumatic actuation, instrumented with embedded sensing and coupled to perception systems, offer a practical middle ground. They add mechanical adaptability where rigid automation fails, and they reduce routine human exposure to hazardous materials. This article examines how such systems function, where they add value in real facilities, realistic limitations and research needs, and the industrial and economic pathways to practical deployment over the next decade.

The operational problem: variability, fragility and hazard

E-waste and hazardous waste streams are hard to standardize: devices arrive in varied condition and orientation, components differ widely in mechanical fragility and contamination risk, and hazardous items (e.g., swollen lithium cells, mercury-containing devices) present acute safety concerns. A successful automation approach must: (1) reliably identify items of interest in noisy visual environments, (2) physically interact without causing breakage or releasing contaminants, and (3) integrate into throughput-driven production lines without excessive downtime or costly retooling.

Rigid robots excel when the object set and poses are constrained. In mixed, damaged, or tangled piles they require complex tooling or risk damaging parts. Human operators bring adaptability but face health and regulatory costs and throughput limits. Soft robots offer compliance and distributed contact, enabling handling strategies that reduce mechanical stress on objects and reduce the likelihood of punctures or brittle failures. These properties are useful but not a universal cure; successful systems must combine hardware, sensing, and control.

Engineering foundations: materials, actuation, sensing, and control

A practical soft-robot cell integrates four engineering layers:

- Materials and structure: Elastomeric bodies; silicones, thermoplastic elastomers, or newer composite polymers; form chambers that deform predictably under pressure. Reinforcements (braided fibers, fabric layers) bias deformation and improve lifetime. Material selection balances flexibility, abrasion resistance, chemical compatibility with residues, and service life under repetitive cycling.

- Pneumatic (or hybrid) actuation: Pneumatics remain attractive for industrial soft manipulators because compressed air is safe around conductive debris and fluids, components are relatively inexpensive, and multiple actuators can be supplied from shared pressurized sources. Practical designs include local pressure regulation, proportional valves, and compact manifolds to achieve responsive force control while keeping energy use manageable. Hybrid approaches (small electric motors plus soft elements) can combine force capacity with compliance where required.

- Embedded sensing: To adapt grasps safely, soft bodies incorporate pressure sensors, flow/pressure monitoring in pneumatic lines, and distributed strain or fiber-optic sensors that report deformation. These tactile channels are complemented with external sensors; RGB cameras, depth cameras, hyperspectral or short-wave infrared imagers, and thermal imaging; which help classify materials and detect hazards (e.g., hot or swollen battery cells).

- Adaptive control and perception: Closed-loop controllers translate sensor feedback into actuation commands. Control strategies range from straightforward force-limiting schemes to model-based controllers leveraging simple deformation models and to learned policies that map perception and tactile inputs to grasp actions. For industrial use, control systems must be robust to sensor noise, to slow system drifts, and to occasional contact events that violate nominal assumptions.

Each layer has trade-offs: more sophisticated sensing and learning increases capability but also integration cost and validation needs. The engineering goal in industrial settings is a balanced design that delivers demonstrable improvement in yield and safety for acceptable capital and operating expense.

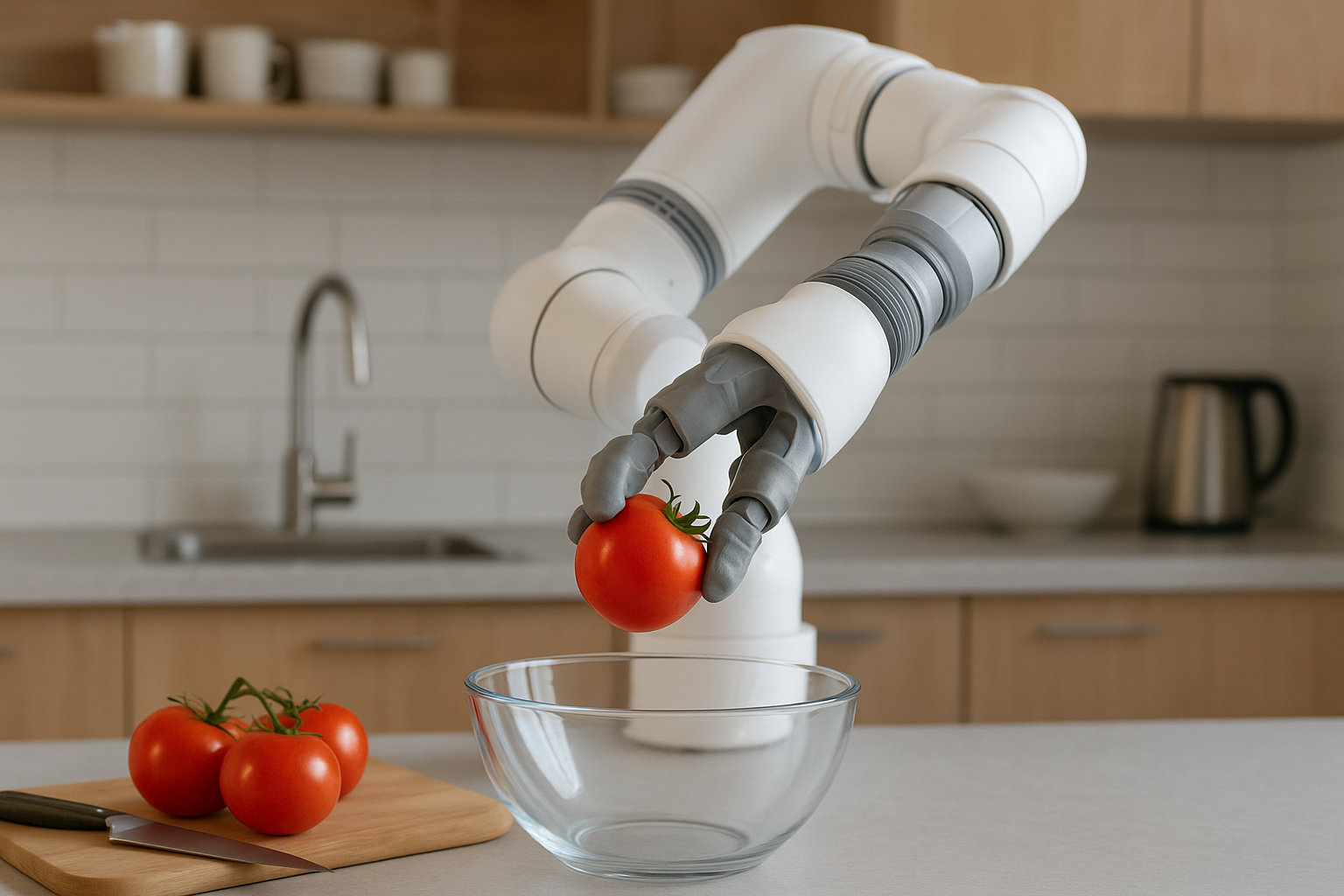

Practical application examples (how soft systems add measurable value)

The value proposition of soft robotics is best understood through concrete, low-risk deployment scenarios:

- Battery handling: Soft grippers with controlled low-pressure enveloping grasps can pick and isolate cylindrical or pouch lithium cells without puncturing casings. When combined with thermal and visual inspection, cells that show deformation or heat anomalies can be routed to safe containment instead of being crushed through shredding.

- PCB and module extraction: Printed circuit boards can be lifted without applying concentrated clamping forces that fracture solder joints or board substrates. Recovering intact modules (connectors, sensors, display assemblies) preserves downstream commercial value and reduces the energy and complexity of metal separation.

- Glass and display removal: Displays and coated glass panels are brittle and often cracked. Compliant suction-assisted soft end-effectors can distribute contact force across larger areas, lowering the risk of fragmentation and reducing the generation of micro-particles.

- Mixed hazardous containers: In laboratory or industrial waste streams, soft arms can manipulate small containers with residues, minimizing splashes or spills while positioning items for controlled neutralization or containment.

These scenarios show how soft manipulation can reduce destructive processing, lower hazardous incidents, and preserve higher-value material fractions; outcomes that translate into operational savings and safer workplaces.

Economic framing and deployment pathway (practical, not speculative)

From an applied economist’s viewpoint focused on execution, the benefits of soft systems appear across three operational levers:

- Labor and safety costs: Automating high-risk sorting steps reduces direct exposure liabilities, personal protective equipment (PPE) costs, and accruals related to occupational health. It also reduces dependence on scarce specialized labor in regulated environments.

- Recovered value: Preserving modular components and intact substrates increases the proportion of material that can be economically re-used or remanufactured rather than sold as low-grade scrap. For mid-scale facilities, this uplift can bridge margins that otherwise make selective recovery uneconomic.

- Flexibility and utilization: Reconfigurable soft cells allow a site to handle variable streams without major mechanical changeovers; the same cell can focus on PCBs one shift and battery isolation the next, improving capital utilization.

Real adoption will be incremental: pilot cells integrated into mixed sorting lines, monitored for yield uplift and incident reduction, followed by measured rollouts where business cases validate payback periods. Expect early adopters in facilities processing high-value urban mining feedstock or in regulated hazardous waste streams where safety gains dominate the economics.

Limitations, validation needs, and research priorities

Soft robotics is promising but not without practical constraints:

- Durability: Elastomers can abrade or chemically degrade; long-term testing under real waste conditions is required to specify maintenance intervals. Design for replaceable contact skins and predictable service modules is pragmatic.

- Control under uncertainty: Pneumatic systems are nonlinear and exhibit delays. Robust, simple control laws with fallback safety behaviors are preferable in production rather than complex policies that are brittle.

- Perception and false positives: Vision and spectral systems can misclassify; conservative decision rules are needed for safety-critical routing (e.g., when in doubt, isolate for human inspection).

- Standards and testing: Industry needs standard test protocols to quantify performance: throughput impact, recoverable fraction uplift, incident reduction, and maintenance costs. These metrics allow operators to compare solutions objectively.

Priority research areas include chemically resistant, long-lived elastomers; compact electro-pneumatic modules for local control; embedded fiber-optic sensing for reliable deformation feedback; and modular software frameworks enabling rigorous validation and traceable safety behaviors.

Societal and workforce implications; realistic transitions

Deployment changes roles rather than simply displacing people. Staff will move toward supervising robotic cells, maintaining the soft hardware, and analyzing process data. Training programs that combine basic maintenance skills with health-and-safety knowledge and data literacy will help facilities transition without social disruption. In regulated sectors, retraining may be a condition of approval and an operational necessity.

Conclusion: A pragmatic outlook

Soft robotics provides a practical set of tools for addressing specific failure modes of today’s recycling systems: handling fragility, reducing hazardous exposure, and enabling selective recovery. The technology does not remove the need for robust process engineering, validated safety protocols, or sensible economic cases. When integrated sensibly —beginning with pilots, rigorous measurement, and iterative redesign —soft robotic systems can improve workplace safety, increase returns from recovered materials, and enable more flexible recycling processes. Over the next 5-15 years, incremental adoption in targeted processes is a realistic pathway to broader industrial impact.

Make Your World Flexible!