A Balanced Technical and Foresight Perspective

Introduction: Why the Kitchen Is Still a Frontier for Robotics

Despite decades of progress in industrial automation, the domestic kitchen remains one of the most resistant environments to robotic assistance. While vacuum cleaners and dishwashers have successfully automated narrow, well-defined tasks, the core activities of food preparation—washing, cutting, peeling, mixing, transferring, and arranging—are still overwhelmingly human-driven.

This is not due to a lack of interest or investment, but rather to the fundamental mismatch between traditional rigid robotic systems and the physical, sensory, and social realities of home kitchens. Food items are soft, deformable, slippery, irregular, and highly variable. Kitchens are shared spaces, not isolated work cells. Users expect safety, adaptability, and intuitive interaction, not industrial precision or speed.

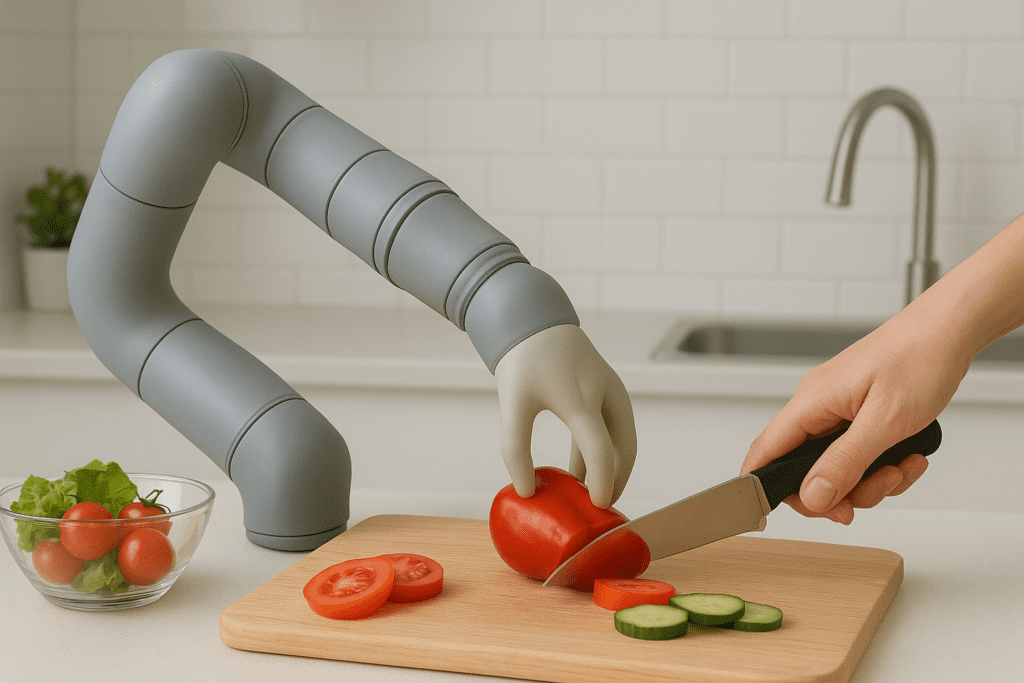

In recent years, soft robotics has emerged as a credible technological pathway to address these constraints. Soft robotic assistants—particularly systems built around soft arms and soft grippers—offer a fundamentally different design philosophy for domestic food preparation: one centered on compliance, physical intelligence, and human-centric interaction.

This article examines the realistic role of soft robotic assistants in home food preparation from a technical and future-oriented perspective, grounded in existing research, current limitations, and plausible development trajectories.

The Nature of Food Preparation as a Robotic Task

Food preparation is not a single task but a sequence of heterogeneous actions involving:

- Handling fragile and deformable objects (fruits, vegetables, dough)

- Managing wet, sticky, or slippery surfaces

- Applying variable force depending on context

- Adapting to visual and tactile uncertainty

- Operating in close proximity to humans

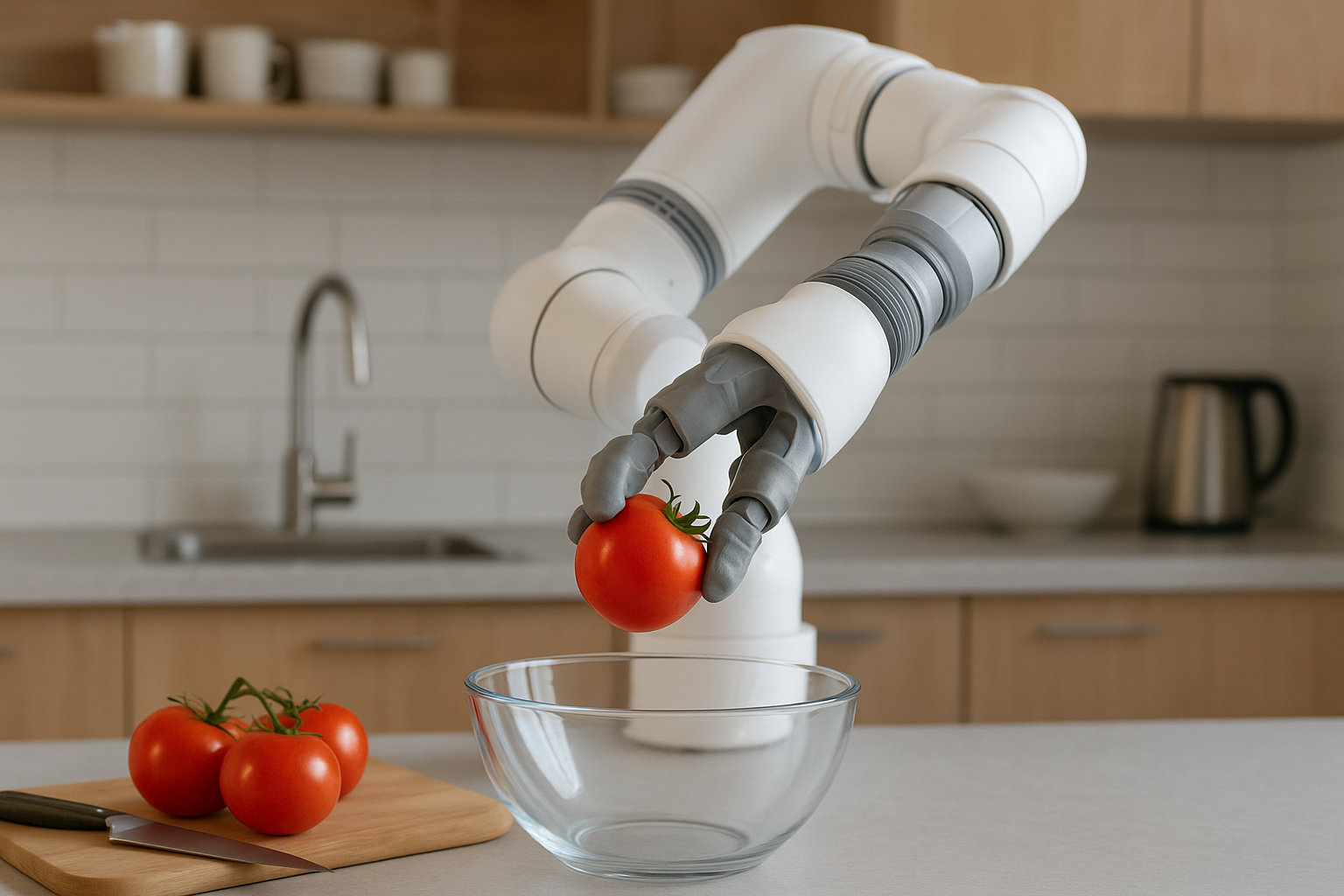

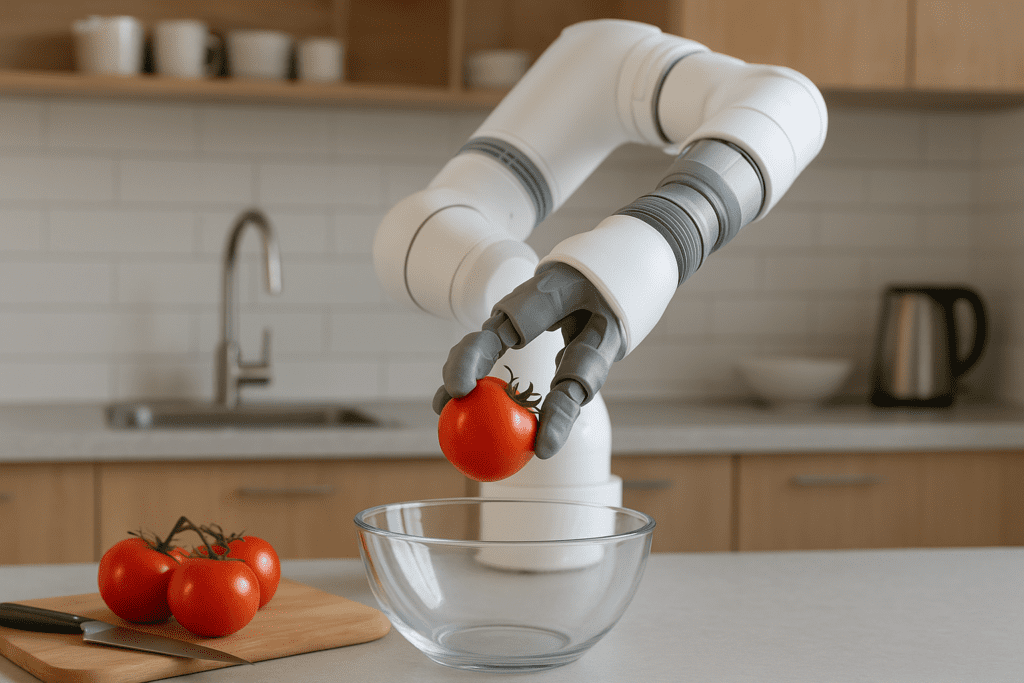

From a robotics standpoint, these characteristics create a worst-case scenario for rigid automation. Even advanced industrial manipulators struggle with tasks such as peeling a banana, transferring cooked pasta, or holding a tomato without bruising it.

Human hands excel at these tasks not because of precise control algorithms, but because of intrinsic compliance, distributed sensing, and continuous adaptation. Soft robotics seeks to replicate part of this physical intelligence at the mechanical level, reducing reliance on exact models or high-bandwidth control.

Soft Robotics: A Brief Technical Foundation

Soft robotic systems are typically constructed using compliant materials such as silicones, elastomers, textiles, or flexible polymers. Actuation is often pneumatic, hydraulic, or tendon-driven, producing motion through deformation rather than rigid joint rotation.

Key characteristics relevant to domestic food preparation include:

- Mechanical compliance: The ability to deform safely upon contact

- Passive adaptability: Conforming to object geometry without precise positioning

- Force distribution: Lower contact stress on delicate items

- Inherent safety: Reduced injury risk in human-shared environments

Academic research from institutions such as Harvard’s Wyss Institute, MIT CSAIL, and the University of Cambridge has repeatedly shown that soft grippers outperform rigid grippers in handling fragile food items, especially when variability is high and sensing is limited.

Why Soft Grippers Matter in the Kitchen

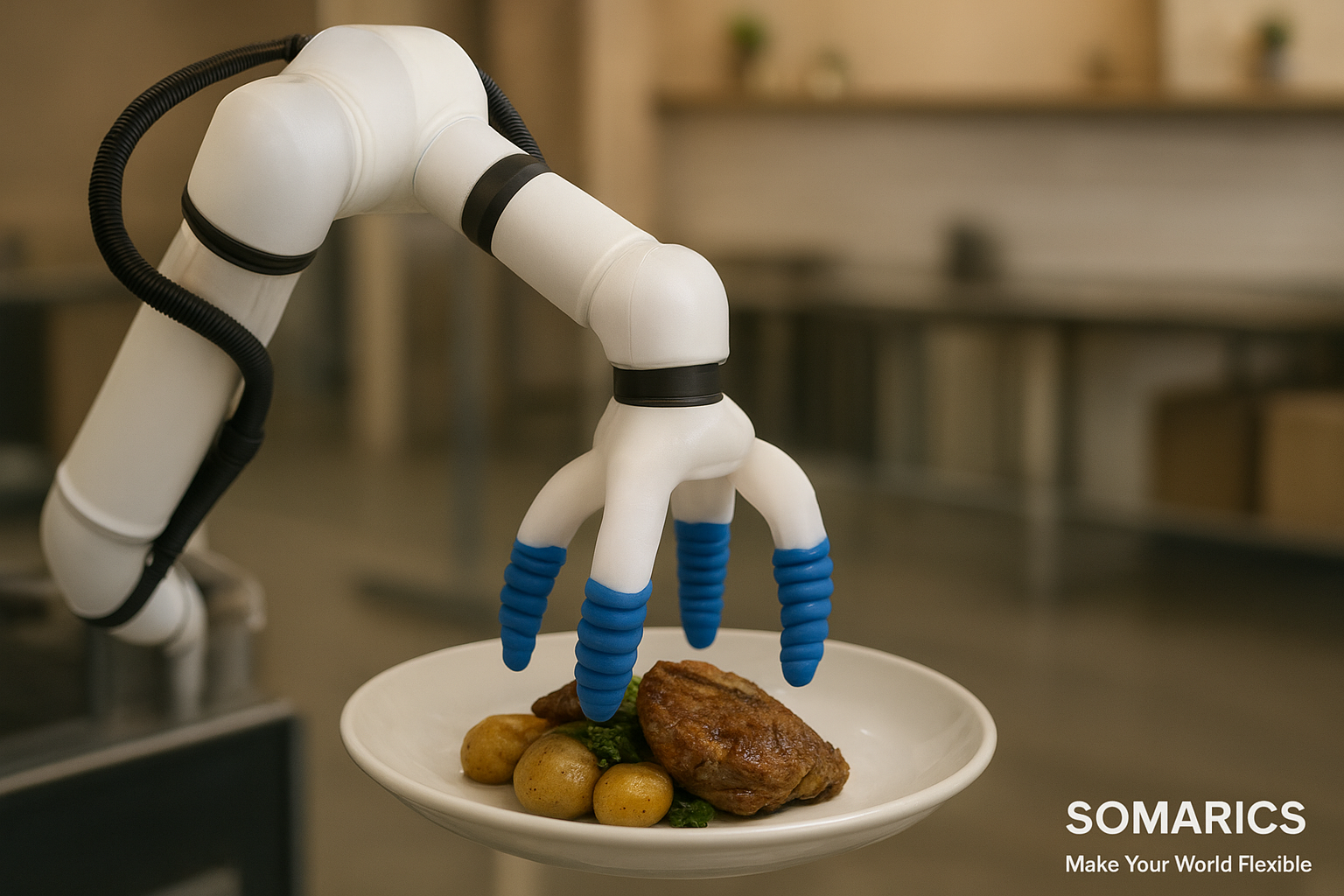

The soft gripper is arguably the most critical component of any domestic food-preparation robot. Unlike industrial grippers optimized for repeatability, kitchen grippers must tolerate uncertainty.

Research prototypes have demonstrated soft grippers capable of:

- Grasping fruits of different sizes without reconfiguration

- Handling items with unknown orientation

- Maintaining grip on wet or oily surfaces

- Releasing objects gently without rebound or drop

Importantly, many of these capabilities arise from material properties rather than software complexity. This shifts part of the “intelligence” from control algorithms to morphology—a core principle of soft robotics known as embodied intelligence.

For home environments, this reduces both cost and system fragility, two major barriers to adoption.

The Role of Soft Robotic Arms in Domestic Contexts

While soft grippers receive most attention, soft or semi-soft robotic arms play an equally important role. In kitchens, reachability, collision tolerance, and spatial flexibility often matter more than positional exactness.

Soft or hybrid arms—combining rigid backbones with compliant segments—can:

- Navigate cluttered countertops

- Absorb accidental human contact

- Adjust posture when encountering unexpected obstacles

- Operate without protective cages or strict safety zoning

Such characteristics align with research trends toward continuum manipulators and variable-stiffness arms, where stiffness can be adjusted based on task requirements.

For example, higher stiffness may be used during cutting assistance, while lower stiffness is preferred during transfer or serving tasks.

Human–Robot Interaction and Trust in the Home

Technical feasibility alone does not determine success in domestic robotics. Social acceptance, perceived safety, and user trust are equally decisive.

Studies in human–robot interaction consistently show that users are more comfortable with robots that:

- Move slowly and predictably

- Appear non-threatening in form and motion

- Respond gracefully to an interruption

- Share control implicitly with humans

Soft robotic assistants naturally satisfy many of these conditions. Their movements tend to be slower, smoother, and more organic than rigid robots. Accidental contact is less alarming. Failure modes are less dramatic.

In food preparation—an activity deeply tied to hygiene, culture, and personal space—these psychological factors are especially important.

What Soft Robotic Assistants Can Realistically Do Today

It is essential to distinguish between realistic near-term applications and long-term visions. Current soft robotic technology is not ready to fully replace human cooking, nor should it aim to.

However, several assistive roles are technically plausible within the next development cycles:

- Ingredient handling: Washing, transferring, and sorting produce

- Pre-preparation tasks: Holding items during cutting performed by humans

- Repetitive preparation steps: Peeling, shelling, or portioning under supervision

- Serving and plating assistance: Transferring prepared food safely

In these roles, the robot acts as an assistant rather than an autonomous chef, augmenting human capability instead of replacing it.

Sensing and Perception: The Remaining Bottleneck

One of the central challenges in soft robotic food preparation is perception. While soft grippers can adapt mechanically, the system still needs to understand what it is handling.

Relevant sensing modalities include:

- Vision (RGB and depth)

- Tactile and pressure sensing

- Force estimation through deformation

- Temperature and moisture sensing (limited use today)

Research increasingly combines soft tactile sensors with machine learning models to estimate object properties such as firmness or ripeness. However, these systems remain sensitive to calibration drift and environmental variation.

For home deployment, robustness and low maintenance are more important than laboratory-level performance.

Hygiene, Materials, and Food Safety Constraints

Food preparation imposes strict material and design constraints rarely encountered in industrial robotics.

Soft robotic components must be:

- Food-safe and non-toxic

- Resistant to oils, acids, and detergents

- Easy to clean or replace

- Resistant to microbial growth

Current research explores food-grade silicones, modular gripper skins, and disposable contact surfaces. These solutions are promising but not yet standardized.

Without clear regulatory pathways and maintenance protocols, large-scale consumer adoption will remain limited.

Energy, Noise, and Domestic Acceptability

Many soft robotic systems rely on pneumatic actuation, which traditionally requires compressors—often noisy and energy-intensive.

For home environments, acceptable solutions must prioritize:

- Low-noise operation

- Compact power units

- Energy efficiency

- Minimal visual clutter

This has driven research into low-pressure pneumatics, compact pumps, and alternative actuation methods such as cable-driven or electroactive polymers. Progress is steady but incremental.

Future Trajectories: From Assistants to Adaptive Systems

Looking ahead 10–20 years, soft robotic assistants for home food preparation are likely to evolve along three axes:

- Integration: Seamless combination of soft manipulation, perception, and user interfaces

- Adaptation: Systems that learn household-specific routines and preferences

- Distribution: Smaller, task-specific assistants rather than monolithic robots

Rather than a single humanoid kitchen robot, the future may involve a network of specialized soft robotic tools embedded into countertops, drawers, or mobile units.

Ethical and Societal Considerations

As with all domestic automation, questions of accessibility, labor displacement, and cultural impact must be addressed carefully.

Soft robotic assistants should be viewed not as replacements for cooking traditions, but as tools that:

- Support aging populations

- Reduce physical strain

- Enable independent living

- Improve safety for people with disabilities

Their value lies in enabling participation, not eliminating human involvement.

Conclusion: A Measured Path Forward

Soft robotic assistants represent one of the most credible pathways toward meaningful robotic support in home food preparation. Their mechanical compliance, inherent safety, and adaptability align naturally with the physical and social realities of the kitchen.

However, progress must remain grounded. Significant challenges remain in sensing, hygiene, reliability, and cost. Overpromising risks undermining trust in the field as a whole.

The future of domestic robotics will not be defined by spectacle, but by quiet usefulness. Soft robotic arms and grippers, thoughtfully designed and carefully integrated, have the potential to become part of everyday life—not as replacements for human skill, but as respectful collaborators within it.