How Gentle Automation Can Transform the Most Fragile Stage of Agriculture?

1. Introduction: The Last Manual Frontier in AgTech

Agriculture is advancing. Autonomous tractors, aerial drones, and smart irrigation systems are already reshaping fields and farms globally.

Yet, in one crucial area, we still rely overwhelmingly on human hands: harvesting the most delicate crops.

Products like mushrooms, microgreens, edible flowers, and fragile herbs remain hand-picked because their texture, fragility, and post-harvest sensitivity make them incompatible with traditional robotic systems.

This isn’t due to a lack of demand for automation, but due to a lack of a solution that’s gentle enough.

At SOMARICS, we believe the future of agriculture doesn’t require more power; it requires more softness.

2. Why Delicate Crop Harvesting Remains Human-Dominated

Despite progress in agricultural robotics, certain crops remain “non-automatable” due to a combination of:

- Low mechanical tolerance (e.g. mushrooms bruise with slight excess force)

- Unpredictable growth patterns (irregular spacing, shapes, or stem orientations)

- Tight spatial configurations (like vertical farms or hydroponic trays)

- Visual or tactile-based ripeness assessment

No rigid gripper, no matter how precise, can consistently harvest a mature basil leaf without risking tearing the adjacent stem.

These tasks require not just manipulation, but compliance, intuition, and adaptability.

That’s where soft robotics begins to show unique promise.

3. Damage, Waste, and Hidden Costs in Delicate Harvesting

The damage caused by poor harvesting methods doesn’t just affect the crop, it affects the entire supply chain:

| Risk Factor | Outcome |

|---|---|

| Overpressure or bruising | Reduced shelf life and market rejection |

| Stem tearing or root damage | Contamination and fungal susceptibility |

| Manual labor inconsistencies | Variability in quality and productivity |

| Delayed harvesting | Lost flavor profiles, stunted regrowth |

In sectors where freshness defines market value, such as edible microgreens sold to Michelin-star restaurants, even microscopic blemishes result in lost sales.

Moreover, labor shortages are intensifying, making the issue not just about quality, but continuity.

4. What Do These Crops Actually Require?

Delicate crop harvesting doesn’t need speed or brute force. It needs three specific capabilities:

- Tactile adaptation – to conform to irregular shapes without crushing

- Gentle closure force – below the bruising threshold of soft tissue

- Navigable form factor – to operate in tightly-packed, sometimes vertical, environments

This combination is fundamentally incompatible with rigid, industrial robot arms or vacuum-suction systems.

It requires a form of robotics that moves more like living tissue than like metal.

5. Soft Robotics: Designed to Adapt, Not Dominate

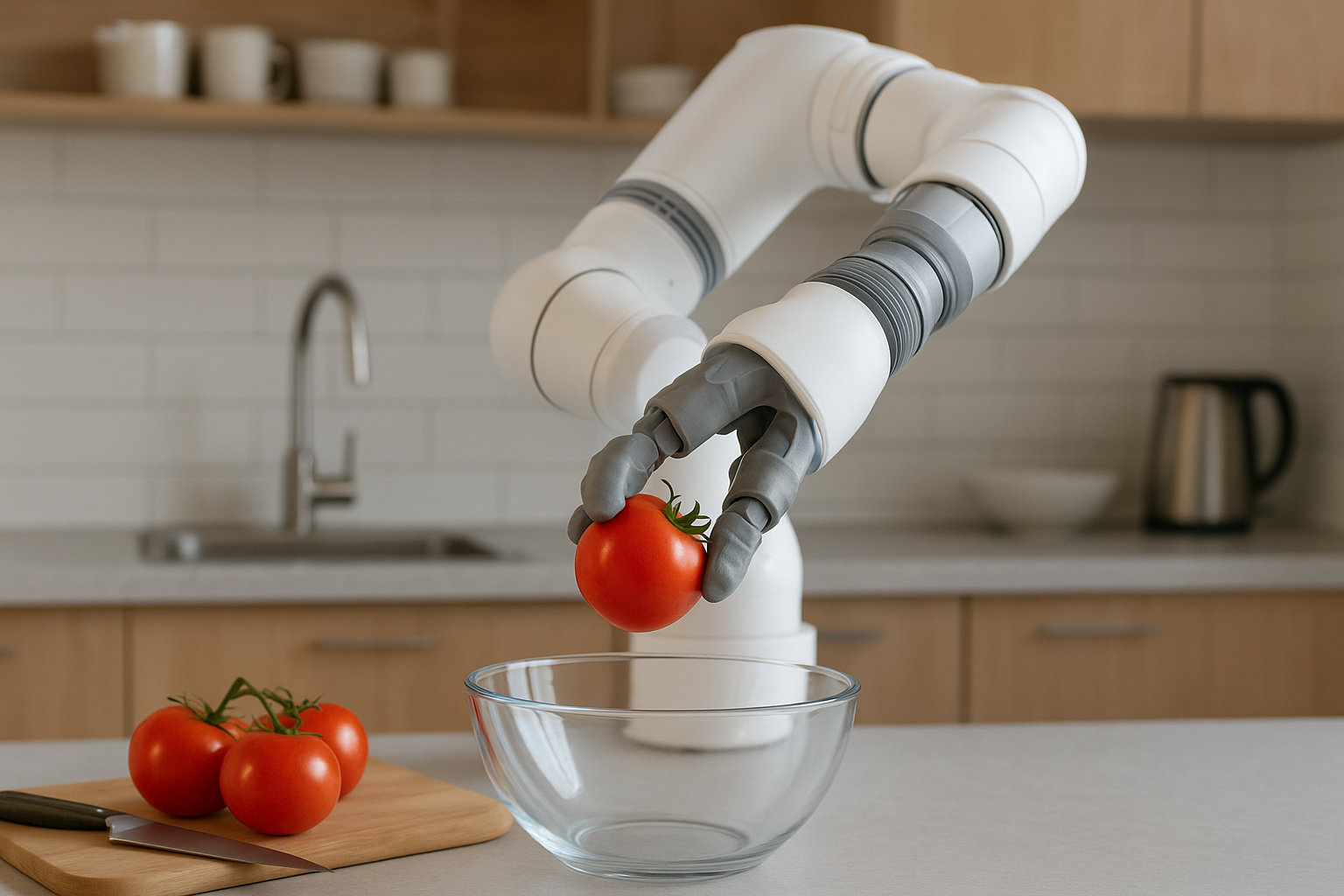

Soft robotics, particularly pneumatically actuated flexible manipulators, offers a radically different approach.

Key characteristics that make soft robots uniquely suited for this task:

- Compliance by default: They deform on contact, rather than resist it.

- Multi-degree flexibility: Ideal for complex navigation within high-density growth zones.

- Material-level gentleness: Silicone or textile-based grippers conform rather than crush.

- Low footprint, modular deployment: They can be installed above trays or moved on rails in vertical farms.

This isn’t about replacing humans entirely. It’s about reducing the human-to-product contact, standardizing harvest quality, and ensuring harvest continuity when labor is scarce or expensive.

6. Practical Applications: From Fungi to Frisée

Let’s break down real-world use cases:

🍄 Mushrooms (e.g., oyster, enoki, shiitake)

- Grow in moist, dark, variable-density environments

- Damage from fingernails or rigid tools leads to contamination

- Soft grippers can pluck individual clusters with no tearing or deformation

🌿 Microgreens

- Extremely lightweight, short-rooted, grown in shallow trays

- Prone to stem snapping during harvest

- Soft blade-like grippers or adaptive compression cuffs can lift, cut, and sort gently

🌸 Edible flowers (e.g., nasturtiums, violets)

- High retail value, zero tolerance for crushing or discoloration

- Soft tip vacuum-foam mechanisms can isolate and pick blooms without contact with petals

🌱 Delicate herbs (e.g., dill, chervil, coriander)

- Require precise, selective cutting

- Soft robot end-effectors integrated with imaging systems can choose the optimal cutting point without damaging the surrounding plant

These aren’t conceptual. These are challenges we at SOMARICS are actively working to solve through design partnerships, in-field trials, and iterative prototyping.

7. How SOMARICS Approaches This Problem Differently

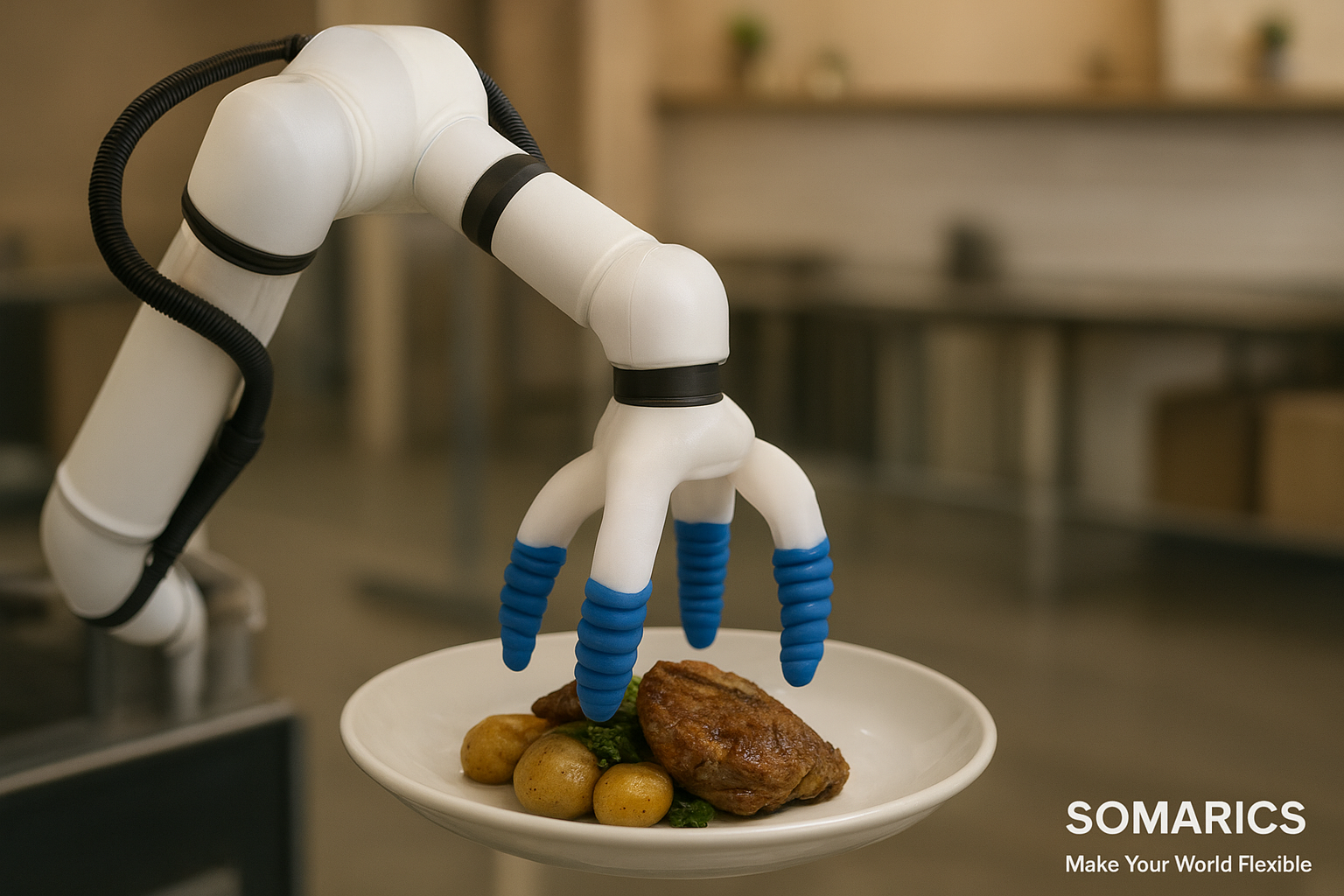

Unlike companies that retrofit traditional arms with “softish” tips, SOMARICS develops fully soft robotic harvesting arms from the ground up.

Our design stack includes:

- Customizable bending actuators adapted to each crop type

- Embedded sensing to detect resistance and adjust grip pressure dynamically

- Replaceable tip modules to switch between grip, lift, cut, or sweep modes

- Mounting flexibility: compatible with rails, gantries, mobile units, or fixed stations

- Low-voltage, low-air systems suitable for indoor farms and greenhouses

Every crop is different. So we don’t offer one tool, we build crop-specific soft robotic solutions in collaboration with growers.

8. Economic and Strategic Advantages of Gentle Harvesting

Here’s what precision soft harvesting enables:

| Benefit | Impact |

|---|---|

| Reduced post-harvest waste | Up to 30% less loss in fragile crops |

| Labor cost mitigation | Less dependency on seasonal or migrant labor |

| Premium product integrity | Higher prices, better brand consistency |

| Scalability for urban farms | Enables automation in constrained environments |

| ESG alignment | Reduced human fatigue, improved biosafety |

In premium produce markets, especially export-grade microgreens, medicinal herbs, or gourmet mushrooms, these advantages translate directly into profit and resilience.

9. Open Doors for Collaboration and Investment

We are currently expanding our ecosystem and actively seeking:

- Growers of sensitive crops to co-develop harvest prototypes

- Greenhouse tech integrators for multi-layer deployment testing

- AgTech VCs and funds exploring automation in high-margin produce

- University partners in plant science and post-harvest quality control

- Export-focused suppliers in Europe, Canada, and the Middle East

This is not a generic solution. This is specialized automation for a specialized problem.

If you’re solving for labor fragility, inconsistent quality, or expanding delicate produce output—SOMARICS wants to talk.

10. Conclusion: Redefining “Precision” in Agriculture

Precision in agriculture has long been defined by control, repetition, and speed.

But with soft robotics, we introduce a new paradigm: precision through adaptation.

The future of harvesting sensitive crops isn’t a faster metal arm, it’s a quieter, softer, more compliant presence. One that respects the product, adapts to nature’s imperfections, and brings new intelligence to the most fragile moment in the food supply chain.

At SOMARICS, we aren’t trying to win the race for speed.

We’re designing to win the race for gentleness, value, and sustainability.

Let’s harvest differently.

Let’s make fragility a strength.