SOMARICS Robotics

Introduction: The Growing Demand for Automation in Logistics!

The logistics industry is evolving rapidly, with global supply chains becoming increasingly complex and the need for faster, more efficient solutions growing. As e-commerce continues to expand, demand for faster deliveries and higher-quality products increases exponentially. Packaging and sorting are essential processes in this equation, where efficiency, speed, and adaptability are non-negotiable. As the volume of goods being handled grows, so does the challenge of maintaining quality control and meeting consumer expectations.

Traditional methods of packaging and sorting often rely on human labor, which, while effective, can be inefficient, costly, and prone to errors. These systems struggle to cope with the rising demand for speed, particularly in high-volume sectors like e-commerce, manufacturing, and food packaging. In an age where customers expect fast shipping and reliable delivery, businesses are under increasing pressure to adapt and meet these expectations.

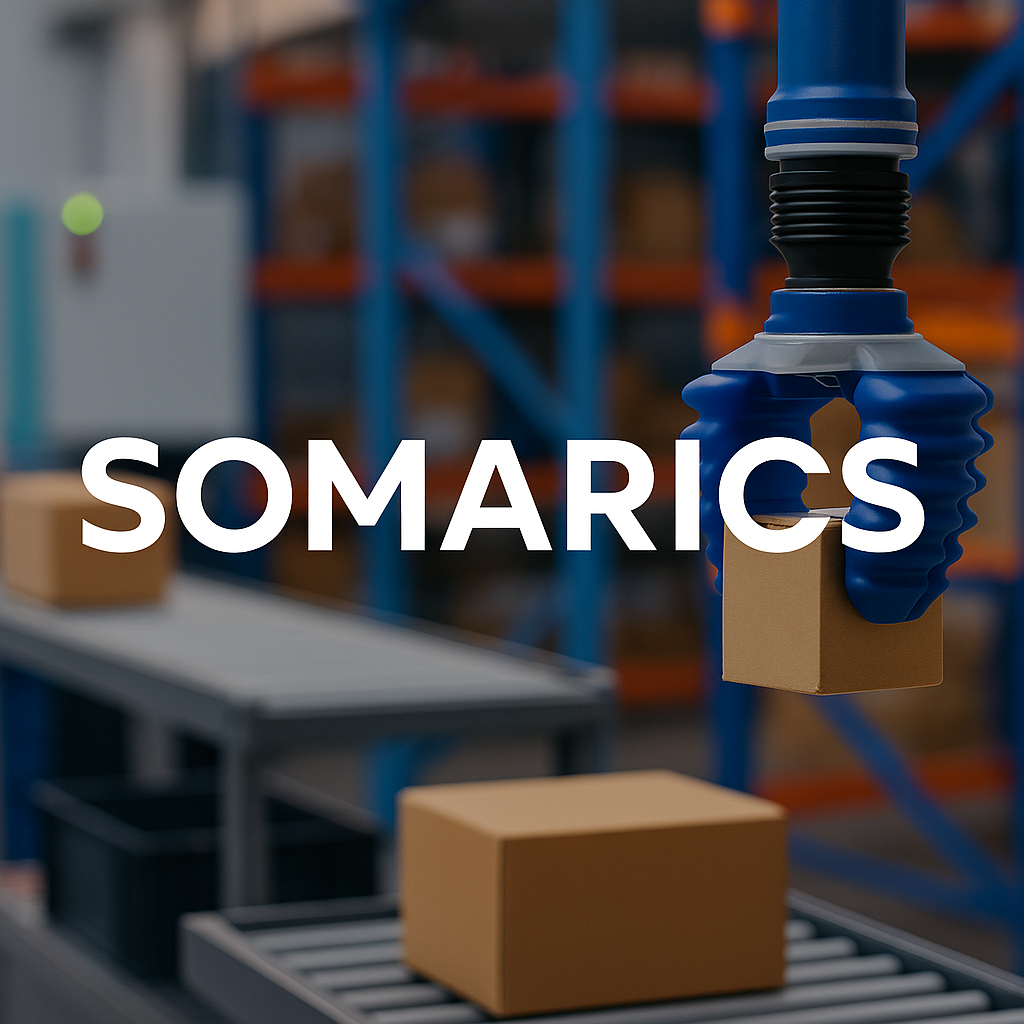

This is where soft robotics comes in as a revolutionary solution. Unlike traditional rigid robots that rely on mechanical movements, soft robots are flexible, adaptive, and designed to handle delicate products with care. They offer the ideal solution for packaging and sorting processes that require gentle handling, adaptability, and high throughput.

How Soft Robotics is Revolutionizing Packaging and Sorting!

Soft robotics is a field of robotics that uses soft materials such as silicone and rubber to create adaptable robots. These robots use pneumatic actuators to mimic human dexterity and flexibility, which allows them to handle various types of materials with a high degree of adaptability. This is a significant advantage in packaging and sorting, where fragile products and irregularly shaped goods often complicate traditional automation systems.

Soft robotics can automate many of the repetitive tasks in packaging, such as placing products in boxes, labeling, and sealing. These robots work continuously, without the need for breaks or rest, increasing throughput and efficiency. By automating these tasks, companies can reduce labor costs while increasing productivity and operational efficiency. Moreover, soft robots are designed to handle delicate items, such as electronics, food products, and pharmaceuticals, without causing damage, unlike traditional robotic systems, which can be too rigid for delicate materials.

One of the most notable features of soft robots is their ability to handle irregularly shaped items. In packaging, where products can range from oddly shaped to fragile, the versatility of soft robotics makes them an invaluable tool. By using pneumatic actuators, soft robots can adjust their grip strength and shape to accommodate the specific needs of different products, preventing damage while maintaining efficiency and performance.

In sorting, soft robots can be equipped with advanced vision systems that enable them to quickly identify and categorize materials. This ability significantly improves sorting efficiency, particularly in industries like e-commerce, where the speed of sorting processes is crucial. Soft robots can easily separate plastics, paper, metal, and other materials, ensuring that the correct materials are processed accurately.

Benefits of Soft Robotics in Packaging and Sorting!

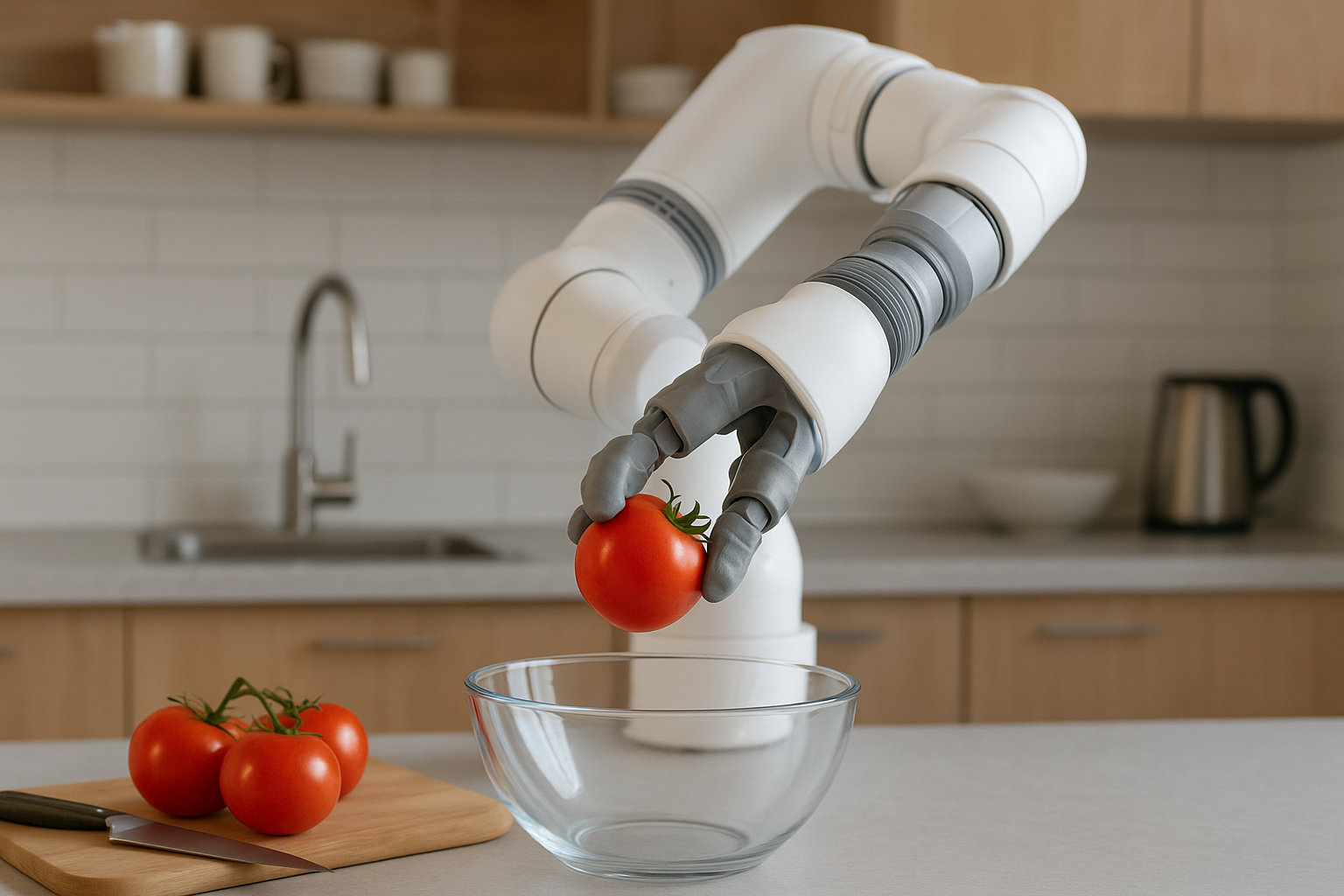

1. Adaptability for Fragile Goods Handling

One of the main benefits of soft robotics is its versatility. Soft robots can easily modify their grip to handle delicate items without causing damage. This is especially important in industries like food packaging, where fragile items such as fruits, vegetables, and baked goods must be handled gently. Similarly, in electronics manufacturing, soft robotics ensures that sensitive components like chips, screens, and wires are treated carefully. Their ability to handle delicate goods makes soft robotics a valuable tool for businesses aiming to improve their packaging and sorting processes.

Soft robots’ ability to adjust dynamically allows them to work across multiple industries, enhancing the efficiency of operations across a wide range of products. This is a significant advantage, as businesses no longer have to rely on a one-size-fits-all approach to their packaging and sorting systems.

2. Increased Speed and Throughput

Efficiency is key in logistics, particularly during peak seasons when demand for faster deliveries is at an all-time high. Soft robots are designed to operate at high speeds without compromising quality. By automating repetitive tasks, they can handle large volumes of goods, increasing throughput and reducing labor costs. Their ability to work non-stop, 24/7, is another factor that boosts productivity in packaging and sorting operations. Soft robotics enables logistics companies to meet tight deadlines and keep pace with rising demand.

Moreover, the ability to operate 24/7 without downtime ensures that facilities can keep pace with increasing demand, especially in fast-moving sectors like e-commerce. This increased speed also means quicker turnaround times for packaged goods, improving delivery efficiency and enhancing customer satisfaction.

3. Improved Sorting Efficiency and Reduced Contamination

In industries like food packaging, maintaining clean and consistent product handling is crucial. Soft robotics enhances sorting efficiency by identifying materials using vision systems and machine learning algorithms. These systems can identify and separate materials, ensuring that only properly categorized products are processed. Similarly, in the logistics sector, soft robots can sort products based on their shape, size, and type, preventing contamination and ensuring that packaging is consistent and accurate.

The ability to sort materials with high accuracy contributes to efficiency and better overall product quality, which is vital for businesses aiming to maintain consumer trust and meet regulatory standards.

4. Reducing Labor Costs and Improving Safety

By automating repetitive and physically demanding tasks, soft robotics helps reduce reliance on human labor, leading to lower operational costs. Additionally, by taking over dangerous tasks—such as handling sharp objects, heavy packages, or hazardous materials—soft robots improve workplace safety. They help create a safer environment for human workers by minimizing exposure to dangerous tasks, reducing injury rates, and ensuring compliance with health and safety regulations.

Soft robotics can also significantly reduce downtime, as these robots work efficiently without the need for breaks. This increases the overall productivity of the facility and ensures that production lines remain operational.

The Future of Soft Robotics in Packaging and Sorting!

The future of packaging and sorting lies in automation. As industries continue to grow and evolve, soft robotics will play an even more significant role in helping businesses meet increasing demands. With the advent of AI-driven soft robots, the capabilities of these robots will continue to improve. Real-time data processing, machine learning, and advanced sensors will enable robots to adapt to changing conditions and improve sorting efficiency.

As more industries adopt sustainable practices and focus on reducing waste, soft robotics will contribute to these goals by improving operational efficiency. By automating sorting and packaging with soft robots, companies can help reduce waste, increase productivity, and contribute to a circular economy.

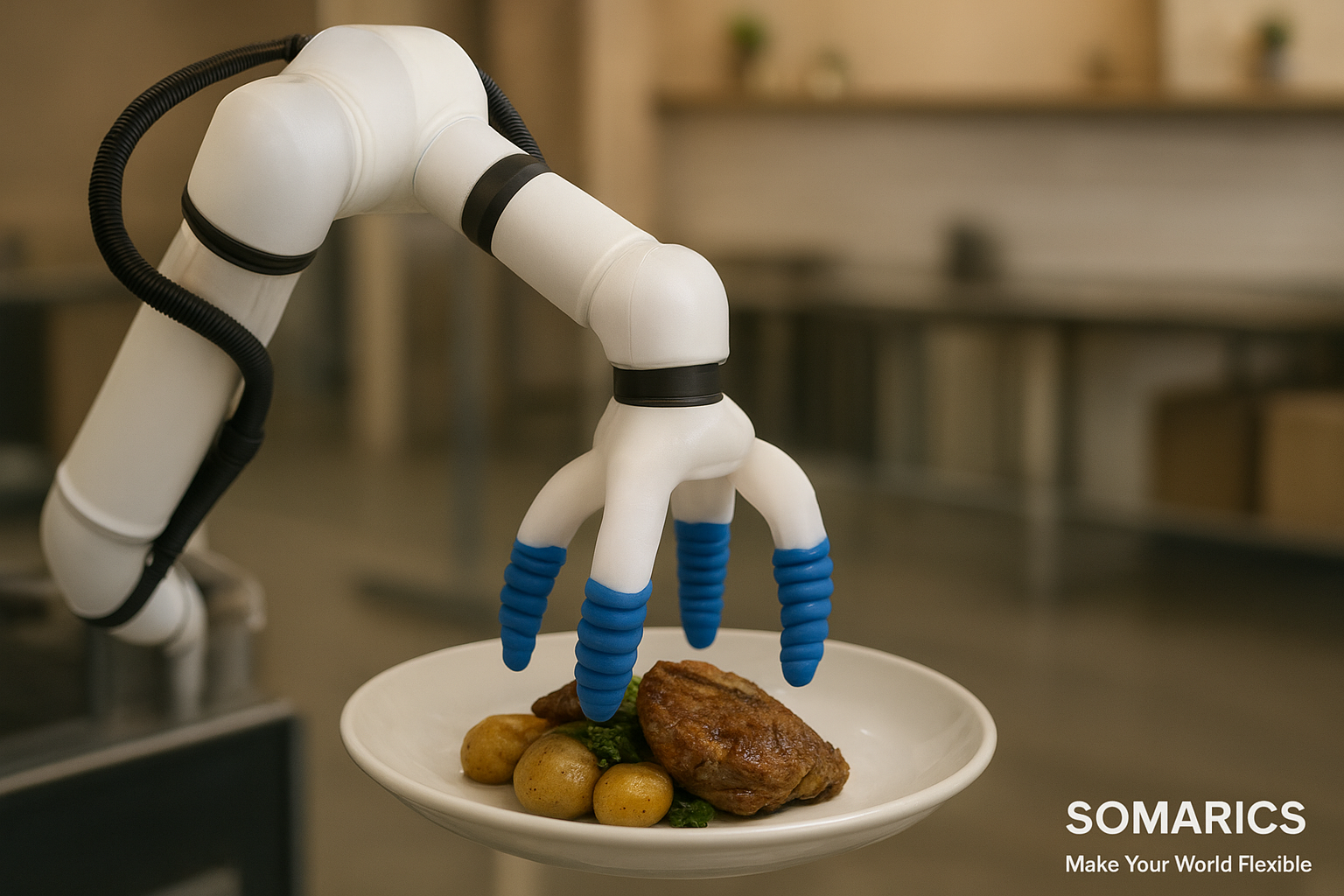

Now: Why Soft Robotics is a Must-Have in the Future of Logistics

Soft robotics is a game-changer for industries that rely on packaging and sorting processes. Its ability to handle delicate items, increase efficiency, improve sorting efficiency, and reduce labor costs makes it an essential tool for businesses striving to remain competitive in a rapidly changing market. As the future of logistics continues to evolve, soft robotics will play a central role in driving sustainability, improving efficiency, and meeting consumer demands for faster, higher-quality service.

To learn more about how soft robotics is transforming packaging and sorting processes, visit SOMARICS Products and discover how our innovative robotic systems can help your business and the environment.